```html

Robbins Hardwood Flooring: A Comprehensive Overview

Robbins Hardwood Flooring represents a prominent brand within the residential and commercial flooring industry. Known for its diverse selection and reputation for quality, Robbins offers a range of hardwood options designed to cater to various aesthetic preferences and budgetary considerations. This article provides an in-depth exploration of Robbins Hardwood Flooring, examining its product offerings, manufacturing processes, durability characteristics, and factors to consider when selecting Robbins for a flooring project.

Established as a brand with a long history, Robbins has evolved to incorporate contemporary manufacturing techniques while maintaining a commitment to delivering aesthetically pleasing and functionally sound flooring solutions. The brand caters to a wide spectrum of consumers, from homeowners undertaking renovations to contractors working on new construction projects. The breadth of their product line allows for customization, ensuring compatibility with diverse design schemes and performance requirements.

Key Point 1: Understanding the Robbins Hardwood Product Line

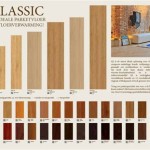

The Robbins Hardwood Flooring product line encompasses a variety of wood species, constructions, and finishes. This diversity allows consumers to select flooring that aligns with their specific design goals and budget. Key aspects of the product line include:

Wood Species: Robbins utilizes a wide array of wood species, each possessing unique characteristics in terms of grain pattern, hardness, and color. Popular options include:

- Oak: Known for its durability and distinctive grain, oak is a widely used hardwood species in flooring. Red oak and white oak are common variations, each offering slightly different visual characteristics.

- Maple: Maple offers a smoother grain pattern than oak, providing a more contemporary aesthetic. It is also known for its hardness and resistance to wear.

- Hickory: Hickory is one of the hardest domestic hardwoods, making it an excellent choice for high-traffic areas. It features a prominent grain pattern and a range of color variations.

- Exotic Species: Robbins often includes exotic hardwood species in their product line, such as Brazilian Cherry or Acacia. These species offer unique colors and grain patterns, providing a distinctive look.

Construction: Hardwood flooring is available in solid and engineered constructions, each offering distinct advantages:

- Solid Hardwood: Solid hardwood consists of planks milled from a single piece of wood. It is known for its longevity and the ability to be refinished multiple times. Solid hardwood is generally recommended for installation above grade.

- Engineered Hardwood: Engineered hardwood is constructed from multiple layers of wood, with a top layer of solid hardwood veneer. This construction provides increased dimensional stability, making it suitable for installation in areas with varying humidity levels, including basements and over concrete slabs.

Finishes: The finish applied to hardwood flooring plays a crucial role in its appearance and durability. Robbins offers a range of finishes, including:

- Polyurethane: Polyurethane finishes provide excellent protection against scratches, stains, and wear. They are available in various sheens, from matte to high gloss.

- Oil Finishes: Oil finishes penetrate the wood, providing a natural look and feel. They require more maintenance than polyurethane finishes but are easier to repair.

- Aluminum Oxide: Aluminum oxide is a durable finish that offers exceptional resistance to abrasion. It is often used in high-traffic commercial settings.

Understanding the nuances of wood species, construction, and finishes is essential when selecting Robbins Hardwood Flooring. Careful consideration of these factors will ensure that the chosen flooring meets the specific requirements of the installation environment and the aesthetic preferences of the consumer.

Key Point 2: Manufacturing Processes and Quality Assurance

The quality and durability of Robbins Hardwood Flooring are directly influenced by the manufacturing processes and quality assurance measures implemented throughout production. These processes typically involve several key stages:

Wood Sourcing: Responsible wood sourcing is a critical aspect of Robbins' manufacturing process. This often involves partnerships with suppliers who adhere to sustainable forestry practices, ensuring the long-term availability of hardwood resources. Certification programs, such as those offered by the Forest Stewardship Council (FSC), may be utilized to verify the sustainability of wood sourcing.

Milling and Shaping: The milling process involves cutting and shaping the raw wood into planks of consistent dimensions. Precise milling is essential to ensure that the planks fit together seamlessly during installation. Advanced machinery and skilled operators are employed to maintain tight tolerances and minimize defects.

Kiln Drying: Kiln drying is a critical step in removing moisture from the wood. This process helps to prevent warping, cupping, and other forms of dimensional instability. The wood is carefully dried to a specific moisture content, which is appropriate for the intended installation environment.

Finishing: The finishing process involves applying multiple coats of finish to the hardwood planks. This process protects the wood from wear, stains, and moisture. The finish is typically applied in a controlled environment to ensure consistent coverage and a smooth, even surface.

Quality Control: Rigorous quality control measures are implemented throughout the manufacturing process. This includes visual inspections, dimensional checks, and performance testing. Defective planks are removed from the production line to ensure that only high-quality flooring reaches the consumer.

Robbins claims to adhere to industry standards and best practices in its manufacturing processes. Understanding these processes can provide consumers with greater confidence in the quality and durability of Robbins Hardwood Flooring.

Key Point 3: Evaluating Durability and Maintenance Requirements

The durability of Robbins Hardwood Flooring depends on several factors, including the wood species, construction, finish, and level of maintenance. Understanding these factors is essential for selecting a flooring option that will withstand the demands of the intended environment.

Wood Species Hardness: The hardness of the wood species is a primary indicator of its resistance to denting and scratching. The Janka hardness scale is a common metric used to measure the hardness of wood. Harder wood species, such as hickory and Brazilian Cherry, are more resistant to wear than softer species, such as pine.

Finish Durability: The type of finish applied to the hardwood flooring plays a significant role in its durability. Polyurethane and aluminum oxide finishes are known for their excellent resistance to scratches, stains, and wear. Oil finishes offer a more natural look and feel but may require more frequent maintenance.

Maintenance Requirements: Proper maintenance is essential for preserving the beauty and longevity of hardwood flooring. Regular sweeping or vacuuming is necessary to remove dirt and debris. Occasional damp mopping with a pH-neutral cleaner is recommended to remove stains and spills. Avoid using harsh chemicals or abrasive cleaners, as these can damage the finish. Periodic refinishing may be necessary to restore the finish and remove scratches or wear marks.

Traffic Levels: Consider the traffic levels in the intended installation area when selecting Robbins Hardwood Flooring. High-traffic areas, such as hallways and living rooms, will require more durable flooring than low-traffic areas, such as bedrooms. Choose a wood species and finish that can withstand the expected level of wear and tear.

By carefully evaluating the durability characteristics and maintenance requirements of different Robbins Hardwood Flooring options, consumers can make informed decisions that will ensure long-lasting performance and satisfaction.

In addition to the factors outlined above, proper installation is crucial for ensuring the longevity and performance of Robbins Hardwood Flooring. Following the manufacturer's installation guidelines is essential for preventing problems such as warping, cupping, and gapping. Professional installation is often recommended, particularly for complex installations or when dealing with solid hardwood flooring.

Furthermore, understanding the warranty offered by Robbins is important. Warranties typically cover manufacturing defects and may offer some protection against finish wear. Review the warranty carefully to understand the terms and conditions. Proper documentation and adherence to the manufacturer's recommendations are necessary to maintain warranty coverage.

When selecting Robbins Hardwood Flooring, consumers should gather information from various sources, including the manufacturer's website, retailers, and online reviews. Consulting with a flooring professional can also provide valuable insights and guidance. By taking a comprehensive approach to the selection process, consumers can make informed decisions that will result in beautiful, durable, and long-lasting hardwood floors.

```

Hardwood Robbins Cask Collection Elite 7 1 2 Rl Wilderness Retreat Flooring Liquidators

Robbins New Line Of Hardwood Flooring

Exploring Flooring Inc

Robbins Natural Forest Totally Tan Hardwood Cornelius Nc Little Wood Flooring Cabinetry

Robbins Artisan Living Oak Engineered Hardwood Flooring In Natural Favorite Arek312s Stafford Tx Roberts Carpet

Robbinshydroguardcraft Brownhardwood Atlanta Ga Moda Floors Interiors

Hardwood Robbins Cask Collection Premier 9 Rl Natural Flooring Liquidators

Robbins Natural Forest Understated Gray Hardwood Cornelius Nc Little Wood Flooring Cabinetry

Robbins Lasting Traditions Oak Engineered Hardwood Flooring In Natural Ltek206s Boston Ma Aj Rose Carpets

Robbins Nature S Canvas Inner Eknc97l12w Hardwood Flooring O K Floors