Quarter Sawn White Oak Flooring Cost: A Comprehensive Guide

Quarter sawn white oak flooring is a premium hardwood flooring option renowned for its stability, distinctive grain patterns, and inherent durability. Its unique cut, derived from a specific milling technique, results in a visually appealing and structurally sound flooring surface. However, this superior quality translates to a higher cost compared to other flooring types. Understanding the various factors influencing the price of quarter sawn white oak flooring is crucial for informed decision-making during the selection and installation process.

The cost of quarter sawn white oak flooring is not solely determined by the price per square foot of the material itself. Several contributing elements, encompassing the wood's grade, thickness, finish, installation requirements, and regional market conditions, collectively shape the total expense. This article provides a comprehensive analysis of these factors, offering insights into the financial implications associated with choosing quarter sawn white oak flooring for residential or commercial spaces.

Factors Influencing the Base Material Cost

The primary expense associated with quarter sawn white oak flooring is the cost of the raw material. This price is influenced by several factors, including the grade of the wood, its thickness, and the width of the planks. Understanding these elements is crucial for budgeting and making informed decisions about the specific type of quarter sawn white oak flooring to purchase.

Grade of Wood: Hardwood flooring is typically graded based on appearance, categorized into grades such as select and better, rift and quartered, and common grades. Select and better grade represents the highest quality, exhibiting minimal imperfections such as knots and color variations. Rift and quartered grade features a more consistent grain pattern due to the specific milling process, often commanding a premium price. Common grades display more character marks and color variations, making them a cost-effective option for those seeking a rustic aesthetic. The higher the grade, the fewer the imperfections, and consequently, the higher the cost per square foot. This is because more of the raw lumber must be discarded during the manufacturing process to achieve a higher, more uniform grade.

Thickness of Planks: The thickness of the quarter sawn white oak flooring planks significantly impacts their durability and longevity. Thicker planks, typically ¾ inch or greater, provide greater stability and can withstand more sanding and refinishing over their lifespan. Thinner planks, such as ½ inch or ⅜ inch, are generally less expensive but may not offer the same level of durability or refinishing potential. The increased material required for thicker planks directly translates to a higher cost per square foot. Furthermore, thicker planks often require more robust subflooring and potentially more specialized installation techniques, adding to the overall project expense.

Width and Length of Planks: The width and length of the planks also play a role in the overall cost. Wider planks, often referred to as wide-plank flooring, create a more expansive and modern look, but they generally cost more due to the increased material required and the potential for greater waste during the milling process. Longer planks tend to be more expensive than shorter planks because they require larger, higher-quality trees to produce. The combination of wider and longer planks can significantly increase the material cost, reflecting the scarcity of such lumber and the enhanced aesthetic appeal.

Finish and Treatment: Pre-finished quarter sawn white oak flooring typically costs more than unfinished flooring. Pre-finished options have already been sanded, stained, and sealed at the factory, saving time and labor during installation. The type of finish applied also impacts the price, with more durable and specialized finishes, such as those containing aluminum oxide or UV protectants, commanding a higher premium. Unfinished flooring, while less expensive initially, requires additional sanding, staining, and sealing after installation, adding to the overall project cost.

Installation Costs Associated with Quarter Sawn White Oak

The installation of quarter sawn white oak flooring contributes significantly to the overall project cost. Labor rates, subfloor preparation, and any necessary modifications to the existing structure all influence the final expense. A thorough understanding of these installation-related factors is essential for accurate budgeting.

Labor Costs: Professional installation is strongly recommended for quarter sawn white oak flooring to ensure proper acclimation, secure fastening, and a flawless finish. Labor costs vary depending on the region, the complexity of the installation, and the installer's experience. Intricate patterns, such as herringbone or chevron, will undoubtedly increase labor expenses compared to a straightforward plank installation. Obtaining multiple quotes from reputable flooring contractors is crucial for securing competitive pricing and ensuring that the installation is performed to the highest standards.

Subfloor Preparation: The condition of the subfloor directly impacts the success and longevity of any hardwood flooring installation. Quarter sawn white oak flooring requires a level, clean, and dry subfloor. Any necessary repairs, leveling, or moisture mitigation measures will add to the overall cost. Self-leveling compounds, plywood underlayment, or vapor barriers may be required to ensure a suitable subfloor, increasing both material and labor expenses. A proper subfloor is critical for preventing issues such as cupping, gapping, and squeaking, which can compromise the flooring's integrity over time.

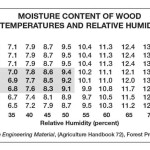

Acclimation: Acclimation is a critical step in the installation process, involving allowing the quarter sawn white oak flooring to adjust to the room's temperature and humidity levels before installation. This process typically takes several days or even weeks, depending on the wood's moisture content and the ambient conditions. Failure to properly acclimate the flooring can lead to dimensional changes after installation, resulting in gaps, buckling, or warping. While acclimation does not directly add to the material or labor costs, it can extend the project timeline and potentially increase labor expenses if installers need to make adjustments due to improper acclimation.

Additional Considerations: Other installation-related costs may include removing existing flooring, disposing of debris, and installing baseboards or trim. These seemingly minor expenses can add up, especially in larger projects. It is essential to factor in these additional costs when creating a comprehensive budget for quarter sawn white oak flooring installation.

Long-Term Cost Benefits and Maintenance

While the initial cost of quarter sawn white oak flooring may be higher than other flooring options, its longevity, durability, and aesthetic appeal can translate to long-term cost benefits. Understanding the maintenance requirements and potential for refinishing is vital for maximizing the value of this investment.

Durability and Longevity: Quarter sawn white oak flooring is known for its exceptional durability and resistance to wear and tear. The unique grain pattern, resulting from the quarter sawing process, makes it less susceptible to warping, cupping, and twisting compared to other cuts of hardwood. This inherent stability contributes to a longer lifespan, potentially reducing the need for replacement or major repairs over time. The added durability can justify the higher initial cost, as the flooring will likely last longer than cheaper alternatives.

Refinishing Potential: Unlike some flooring types that require complete replacement when damaged or worn, quarter sawn white oak flooring can be sanded and refinished multiple times. This refinishing capability extends the flooring's lifespan and allows homeowners to update the look and feel of their space without incurring the expense of complete replacement. The number of times a floor can be refinished depends on the thickness of the wear layer. Thicker planks generally allow for more refinishing cycles, further enhancing the long-term value.

Maintenance Requirements: Proper maintenance is essential for preserving the beauty and integrity of quarter sawn white oak flooring. Regular sweeping or vacuuming to remove dirt and debris, along with occasional damp mopping with a pH-neutral cleaner, will help prevent scratches and maintain the finish. Using floor protectors under furniture legs and avoiding abrasive cleaning products are also recommended. While maintenance costs are relatively low, neglecting proper care can lead to premature wear and damage, potentially reducing the flooring's lifespan and requiring more frequent refinishing or repairs.

Resale Value: Hardwood flooring, particularly premium options like quarter sawn white oak, can significantly increase a home's resale value. The perceived quality and timeless appeal of quarter sawn white oak flooring can be a major selling point for potential buyers. Investing in high-quality flooring demonstrates a commitment to craftsmanship and lasting value, making the property more attractive in the real estate market.

In conclusion, the cost of quarter sawn white oak flooring is a multifaceted issue influenced by various factors ranging from the grade and thickness of the wood to installation expenses and long-term maintenance requirements. While the initial investment may be higher compared to other flooring options, the inherent durability, refinishing potential, and aesthetic appeal of quarter sawn white oak can translate to long-term value and enhanced property value. A thorough understanding of these factors is critical for making informed decisions and ensuring a successful flooring project.

3 1 4 X White Oak Select Better Quarter Sawn Only Unfinished Solid Hardwood Flooring

Quarter Rift Sawn Bare White Oak Flooring Gaylord

Rift And Quarter Sawn Oak Flooring

Rift Quarter White Oak Flooring Vermont Plank

Rift And Quarter Sawn Oak Flooring

8 X 3 4 White Oak Character Live Sawn European Style 2 To 10 Unfinished Solid Hurst Hardwoods

Rift Quarter White Oak Flooring Vermont Plank

Quartersawn And Rift Sawn White Oak Hardwood Flooring 8 33 Butcher Block Countertops More Country Mouldings

Carlisle S Quarter Sawn White Oak It A Grain Thing Wide Plank Floors

Discount 2 1 4 X 3 White Oak Common Rift Quartered Unfinished Solid By Hurst Hardwoods

Related Posts