Best Underlayment For Engineered Hardwood Flooring

Engineered hardwood flooring presents a popular choice for homeowners due to its aesthetic appeal, durability, and relatively easier installation compared to solid hardwood. However, the success of an engineered hardwood floor installation heavily relies on selecting the appropriate underlayment. The underlayment acts as a crucial intermediary layer between the subfloor and the finished flooring, providing numerous benefits that contribute to the floor's longevity, comfort, and overall performance. Choosing the wrong underlayment can lead to a multitude of problems, including moisture issues, insufficient sound insulation, and premature wear and tear of the flooring. Therefore, understanding the different types of underlayment available and their respective properties is essential for making an informed decision.

This article aims to provide a comprehensive guide to selecting the best underlayment for engineered hardwood flooring. It will explore the various types of underlayment materials, their advantages and disadvantages, the factors to consider when choosing underlayment, and specific recommendations based on different flooring needs and subfloor conditions. The information presented will enable homeowners and flooring professionals to make well-informed decisions, ensuring a successful and long-lasting engineered hardwood floor installation.

Understanding the Role of Underlayment

Underlayment serves multiple crucial functions in an engineered hardwood flooring installation. Its primary purpose is to create a smooth, level surface for the flooring to rest upon, minimizing imperfections in the subfloor. This is particularly important in older homes or buildings where the subfloor may have slight variations in height or minor surface irregularities. By providing a consistent and even base, the underlayment helps to prevent the engineered hardwood planks from flexing or bending underfoot, which can lead to premature wear and tear, squeaking, and even plank separation over time.

Another significant function of underlayment is to provide moisture protection. Subfloors, especially concrete slabs, can be susceptible to moisture migration from the ground. This moisture can then wick up into the engineered hardwood, causing warping, cupping, and mold growth. Underlayment with a built-in moisture barrier helps to prevent moisture from reaching the flooring, thereby protecting its structural integrity and extending its lifespan. The effectiveness of a moisture barrier is often measured by its Perm rating, with lower Perm ratings indicating better moisture resistance.

Sound insulation is another vital benefit provided by underlayment. Engineered hardwood floors, like other hard surface flooring options, can transmit sound easily, particularly in multi-story buildings. Underlayment with sound-dampening properties helps to absorb impact noise and reduce airborne sound transmission, creating a quieter and more comfortable living environment. The sound reduction performance of underlayment is typically measured by its Impact Insulation Class (IIC) and Sound Transmission Class (STC) ratings, with higher ratings indicating better sound insulation.

Finally, underlayment can provide a degree of thermal insulation, helping to keep the floor warmer in colder climates. This is especially beneficial for floors installed over concrete slabs, which can be cold to the touch. The thermal resistance of underlayment is measured by its R-value, with higher R-values indicating better insulation.

Types of Underlayment Materials

The market offers a diverse range of underlayment materials, each possessing unique properties and offering different benefits. Understanding the characteristics of each type is crucial for selecting the appropriate underlayment for a specific engineered hardwood flooring project. Some of the most common types include:

Foam Underlayment: Foam underlayment is a popular and affordable option, typically made from polyethylene or polyurethane foam. It provides good cushioning and sound insulation, making it a suitable choice for residential applications. Foam underlayment is also lightweight and easy to install. However, it may not be the best option for areas with high moisture levels or heavy foot traffic, as it can compress over time and lose its effectiveness.

Cork Underlayment: Cork underlayment is a natural and sustainable option derived from the bark of cork oak trees. It offers excellent sound and thermal insulation, as well as natural resistance to mold and mildew. Cork underlayment is also durable and resilient, able to withstand heavy foot traffic without compressing significantly. However, it is generally more expensive than foam underlayment and may require professional installation.

Rubber Underlayment: Rubber underlayment is known for its superior sound insulation and durability. It is typically made from recycled rubber, making it an environmentally friendly option. Rubber underlayment is also resistant to moisture and mold, making it suitable for use in basements and other areas prone to dampness. However, it can be more expensive and heavier than other types of underlayment.

Felt Underlayment: Felt underlayment is a dense and durable option often made from recycled fibers. It provides good sound insulation and cushioning, and is resistant to compression. Felt underlayment is also relatively affordable and easy to install. However, it may not be the best choice for areas with high moisture levels, as it can absorb water.

Combination Underlayment: Combination underlayment products combine different materials to offer a broader range of benefits. For example, some combination underlayments feature a foam core with a moisture barrier layer, providing both cushioning and moisture protection. These products can be a good option for homeowners who want to simplify the installation process and address multiple flooring needs with a single product.

Factors to Consider When Choosing Underlayment

Selecting the best underlayment for engineered hardwood flooring requires careful consideration of several factors. These factors include the subfloor condition, the flooring type, the intended use of the space, and any specific needs or concerns.

Subfloor Condition: The condition of the subfloor is a critical factor in determining the appropriate type of underlayment. If the subfloor is uneven or has minor imperfections, a thicker underlayment with good cushioning properties may be necessary to create a smooth and level surface. If the subfloor is prone to moisture, an underlayment with a built-in moisture barrier is essential to protect the engineered hardwood flooring. For concrete subfloors, it's crucial to test for moisture levels before installing any underlayment, and to choose an underlayment specifically designed for concrete.

Flooring Type: The type of engineered hardwood flooring being installed can also influence the choice of underlayment. Thinner engineered hardwood planks may require a thicker underlayment to provide adequate support and cushioning. Some engineered hardwood flooring manufacturers may specify certain types of underlayment that are compatible with their products. Always consult the manufacturer's recommendations before selecting underlayment.

Intended Use of Space: The intended use of the space where the engineered hardwood flooring is being installed should also be considered. In areas with high foot traffic, such as hallways or living rooms, a durable and compression-resistant underlayment is recommended. In bedrooms or home theaters, sound insulation may be a primary concern, necessitating an underlayment with high IIC and STC ratings. For bathrooms or kitchens, moisture resistance is paramount, making an underlayment with a built-in moisture barrier essential.

Specific Needs and Concerns: Homeowners may have specific needs or concerns that influence their choice of underlayment. For example, individuals with allergies may prefer an underlayment that is hypoallergenic and resistant to mold and mildew. Homeowners concerned about environmental sustainability may opt for a recycled or natural underlayment option. Homes with radiant heating systems require a special type of underlayment specifically designed to allow heat transfer. Compliance with building codes or regulations may also dictate specific underlayment requirements.

Thickness: Underlayment thickness typically ranges from 2mm to 10mm or more. The appropriate thickness depends on the subfloor condition and the desired level of cushioning and sound insulation. A thicker underlayment can help to bridge minor imperfections in the subfloor and provide better sound absorption, but it may also increase the overall height of the floor, potentially creating transitions issues with adjacent flooring surfaces.

Density: Underlayment density affects its durability and compression resistance. A denser underlayment is generally more resistant to compression under heavy foot traffic, ensuring that it maintains its cushioning and sound insulation properties over time.

Moisture Barrier: If moisture is a concern, choose an underlayment with an integrated moisture barrier. The moisture barrier should be thick enough to effectively prevent moisture from migrating from the subfloor to the flooring. Pay attention to the Perm rating, with lower values indicating better moisture resistance.

Sound Insulation: If sound insulation is a priority, look for an underlayment with high IIC and STC ratings. The higher the ratings, the better the sound insulation provided by the underlayment. Consider the specific noise concerns in the space when selecting underlayment with appropriate sound-dampening properties.

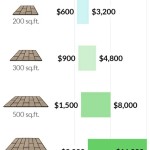

Cost: The cost of underlayment can vary significantly depending on the material, thickness, and features. While it is important to stay within budget, it is also crucial to prioritize quality and performance. Choosing a cheap underlayment may save money upfront, but it could lead to problems down the road, such as premature wear and tear of the flooring or inadequate sound insulation, ultimately costing more in the long run.

By carefully considering all of these factors, homeowners and flooring professionals can select the best underlayment for their specific engineered hardwood flooring project, ensuring a successful and long-lasting installation.

Underlayment Buyer S Guide

Hardwood Floor Underlayment Ultimate Guide

Underlayment Buyer S Guide

Does Wood Flooring Need Underlay Greyspace

Flooring 101 Best Underlayment For Hardwood Floors Next Day

Flooring Underlayment Non Toxic Effective Green Building Supply

The Best Underlayment For Hardwood Flooring Dalton Center

The Top Reasons Why You Need An Underlayment For Hardwood Floors

Underlayment What It Is And Why You Need Stuga

Hardwood Floor Underlayment Flooring And Design

Related Posts