Non-Static Flooring: Essential Aspects to Consider

Non-static flooring is a critical element in industries and facilities that are prone to electrostatic discharge (ESD), which can damage sensitive electronic equipment and pose safety hazards. Understanding the essential aspects of non-static flooring is crucial for ensuring a safe and efficient work environment.

Conducting vs. Static Dissipative Flooring

Non-static flooring is classified into two main types: conducting and static dissipative. Conducting flooring has a low electrical resistance, allowing static charges to flow through it to the ground. Static dissipative flooring, on the other hand, has a higher electrical resistance but still allows static charges to dissipate gradually, preventing them from accumulating to dangerous levels.

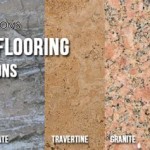

Floor Covering Materials

Various materials can be used for non-static flooring, including vinyl, rubber, and epoxy. Vinyl and rubber tiles are commonly used for their耐久性, ease of installation, and anti-fatigue properties. Epoxy flooring provides a smooth, seamless surface ideal for areas requiring high cleanliness levels.

Conductive Grids and Raised Flooring

In some cases, it may be necessary to install a conductive grid beneath the floor covering. This grid creates a conductive path for static charges to flow through, ensuring uniform dissipation throughout the flooring. Raised flooring is another option, elevating the floor surface to allow the installation of service cables and provide better air circulation.

Grounding and Bonding

Proper grounding and bonding is essential for the effective functioning of non-static flooring. Grounding connects the flooring to the earth, providing a path for static charges to dissipate. Bonding ensures that all conductive components connected to the flooring are electrically interconnected, creating a continuous path for static discharge.

Maintenance and Inspection

Regular maintenance and inspection are crucial to maintain the effectiveness of non-static flooring. Cleaning the floor with approved cleaning solutions helps remove dirt and contaminants that can reduce conductivity. Periodic inspections should be conducted to identify any damage or wear that may compromise the flooring's ESD properties.

Conclusion

Non-static flooring is an essential element in ESD-sensitive environments, providing a safe and efficient work environment. By considering the essential aspects of non-static flooring, including floor covering materials, conductive grids, grounding, and maintenance, facilities can ensure that their flooring meets the required ESD standards and contributes to the overall safety and productivity of their operations.

How Anti Static Flooring Protects Against Damaging Electro Discharges Esd

Protexion Anti Static Floor Coating Paint Manufacturers Suppliers In Nnashik Pune Aurangabad Raangaon Faltan Kurkumbh Pimpri Chinchwad Chakan Khed Shivapur Shikrapur Walu Chikhal Thane Shendra Surat Hazira Palsana Vapi

Esd Flooring Anti Static Floor Solutions Bondline

Non Bubble Hpl All Steel Anti Static Access Floor For Server Rooms China Building Material Tile Made In Com

The Difference Between Pvc Plastic Floor And Anti Static Titanflor

Hospital Vinyl Flooring Non Anti Static Thickness 2 Mm At Rs 185 Sq Ft In Vadodara

Non Bubble Hpl All Steel Anti Static Access Floor For Server Rooms China Building Material Tile Made In Com

Anti Static Vinyl Flooring At Rs 52 Square Feet In Navi Mumbai Carpetmen Interiors

Protexion Anti Static Floor Coating Paint Manufacturers Suppliers In Nnashik Pune Aurangabad Raangaon Faltan Kurkumbh Pimpri Chinchwad Chakan Khed Shivapur Shikrapur Walu Chikhal Thane Shendra Surat Hazira Palsana Vapi

Anti Static Vinyl Flooring For Indoor Thickness 2mm At Rs 180 Sq Ft In Ludhiana

Related Posts