Essential Aspects of Walk-In Cooler Replacement Flooring

Walk-in coolers are essential equipment in the food service and retail industries, providing chilled storage for perishable items. However, the flooring in walk-in coolers endures constant wear and tear, making replacement necessary over time. This article explores key aspects to consider when replacing flooring in a walk-in cooler.

Type of Flooring Material

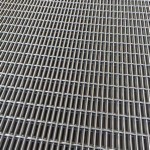

Selecting the appropriate flooring material is crucial. Typical options include:

- Galvanized Steel: Durable and resistant to moisture, but prone to dents and corrosion.

- Aluminum: Lightweight and corrosion-resistant, but more expensive than steel.

- Polymer: Impact-resistant and easy to clean, but not as durable as metal options.

Floor Drainage

Effective drainage is essential to prevent water accumulation and potential slip hazards. Consider the following:

- Slope: The floor should be sloped towards a drain to facilitate water runoff.

- Drain Location: Place the drain in an accessible location for easy cleaning and maintenance.

- Drain Type: Choose a drain that prevents debris from clogging the system.

Anti-Slip Properties

Slippery floors pose a safety risk. Ensure the chosen flooring material has anti-slip properties to prevent accidents and falls.

Durability and Longevity

Walk-in cooler flooring endures heavy foot traffic and frequent cleaning. Select a flooring material that can withstand these demands and last several years.

Maintenance and Cleaning

Regular maintenance and cleaning are essential to extend the life of the flooring. Consider a material that is easy to clean and does not require specialized cleaning methods.

Professional Installation

Proper installation is vital for the performance and longevity of the flooring. Engage a reputable contractor with experience in walk-in cooler flooring replacement.

Other Considerations

Additional factors to consider include:

- Health Regulations: Comply with local health codes regarding flooring materials for food storage areas.

- Warranty: Obtain a warranty from the manufacturer or installer to ensure quality and protect against defects.

- Cost: Determine the budget for the replacement and compare quotes from different contractors.

Conclusion

Replacing the flooring in a walk-in cooler is an essential investment that ensures optimal performance and safety. By considering the discussed aspects – flooring material, drainage, anti-slip properties, durability, maintenance, professional installation, and other factors – you can make an informed decision to extend the lifespan of your walk-in cooler and protect your business.

Best Flooring Options For Walk In Coolers And Freezers

Walk In Floors 101 Arctic Coolers Freezers

Seal Tex Walk In Floors

Best Flooring Options For Walk In Coolers And Freezers

Best Flooring Options For Walk In Coolers And Freezers

What Are Your Walk In Cooler Flooring Options 512 Refrigeration

Seal Tex Walk In Floors

Seal Tex Walk In Floors

Cold Storage Freezer Flooring Floor Repair Spectrum Industrial Floors

Re Skin It Ameritech Facility Services

Related Posts