The Indispensable Role of the Vinyl Flooring Installation Roller

Vinyl flooring installation is a common and relatively straightforward process in home improvement and commercial construction. While often perceived as a simpler alternative to other flooring types, achieving a professional, long-lasting vinyl floor requires attention to detail and the use of appropriate tools. Among these tools, the vinyl flooring installation roller stands out as a critical element, significantly impacting the final appearance, durability, and overall lifespan of the floor.

The roller, a seemingly simple device, plays a crucial role in ensuring proper adhesion between the vinyl flooring material and the subfloor. Effective adhesion is not merely about aesthetics; it’s about preventing a host of potential problems ranging from unsightly bubbles and warps to premature wear and tear. This article delves into the importance of the vinyl flooring installation roller, exploring its functions, types, proper usage, and the potential consequences of neglecting this essential tool.

Ensuring Proper Adhesion: The Primary Function

The primary function of a vinyl flooring installation roller is to ensure complete and uniform adhesion of the vinyl sheet or tile to the subfloor. Vinyl flooring relies on an adhesive layer, either pre-applied or spread separately, to bond it to the underlying surface. Without adequate pressure applied during installation, air pockets can become trapped beneath the vinyl, creating bubbles or weak spots. Over time, these imperfections can lead to the vinyl lifting, cracking, or becoming susceptible to moisture damage.

The roller works by applying consistent and even pressure across the entire surface of the vinyl as it's being laid. This pressure forces out any trapped air, ensuring the adhesive makes full contact with both the vinyl backing and the subfloor. The result is a strong, durable bond that can withstand foot traffic, furniture weight, and temperature fluctuations without compromising the integrity of the floor.

The effectiveness of the roller depends on several factors, including its weight, width, and the material it's made from. Heavier rollers generally provide more consistent pressure, while wider rollers cover more surface area in a single pass, reducing installation time. The material of the roller also plays a role; rollers designed for vinyl flooring are typically made from non-marking materials that won't damage or scuff the surface of the vinyl.

Furthermore, the type of adhesive used significantly impacts the need for a thorough rolling process. Some adhesives require more pressure to activate and achieve a strong bond. Consulting the adhesive manufacturer's instructions is crucial to determining the appropriate rolling technique and the recommended weight of the roller for optimal results.

Types of Vinyl Flooring Rollers: A Comprehensive Overview

Vinyl flooring rollers are available in a variety of types, each designed to cater to different project sizes, flooring types, and installer preferences. Understanding the characteristics of each type is essential for selecting the right roller for a specific installation.

Hand Rollers: These are typically smaller, lighter rollers designed for smaller areas or detail work. They are ideal for pressing down edges, corners, and seams where a larger roller might be unwieldy. Hand rollers are generally made of rubber or plastic and are easy to maneuver, making them suitable for DIY projects or intricate installations.

Walk-Behind Rollers: These rollers are significantly larger and heavier than hand rollers, designed for covering large areas quickly and efficiently. They typically feature a long handle that allows the installer to apply pressure while walking, minimizing fatigue. Walk-behind rollers are available in various weight classes, with heavier rollers providing more force for a stronger bond.

Weighted Rollers: Weight is a significant factor in the effectiveness of a vinyl flooring roller. Weighted rollers, whether hand-held or walk-behind, are designed to provide consistent pressure across the entire surface of the vinyl. The weight helps to ensure that the adhesive makes full contact with the subfloor, eliminating air pockets and promoting a strong, durable bond. The appropriate weight of the roller depends on the type of vinyl flooring and the adhesive used.

Seam Rollers: These specialized rollers are designed specifically for pressing and sealing seams between vinyl sheets or tiles. They typically feature a narrow, rounded edge that concentrates pressure on the seam, creating a tight, waterproof seal. Seam rollers are essential for ensuring the longevity and aesthetic appeal of vinyl flooring in areas prone to moisture, such as bathrooms and kitchens.

Choosing the right roller type depends on the scope of the project and the specific characteristics of the vinyl flooring. For small areas or intricate installations, a hand roller may suffice. For larger projects, a walk-behind roller is more efficient. Regardless of the type chosen, ensuring the roller is clean and in good working condition is crucial for achieving optimal results.

Proper Usage and Technique: Maximizing Effectiveness

Even with the right type of roller, proper usage and technique are paramount to achieving a successful vinyl flooring installation. Incorrect rolling techniques can lead to uneven adhesion, surface damage, and ultimately, a compromised floor.

Subfloor Preparation: Before rolling, ensuring the subfloor is clean, level, and dry is essential. Any debris, imperfections, or moisture can interfere with the adhesive bond and create problems down the line. Thoroughly vacuuming and leveling the subfloor are crucial steps in the preparation process.

Adhesive Application: Applying the correct amount of adhesive is critical. Too little adhesive will result in a weak bond, while too much adhesive can create a messy installation and hinder the rolling process. Following the adhesive manufacturer's instructions is crucial for determining the appropriate application rate.

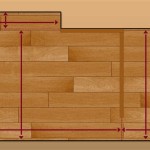

Rolling Technique: The rolling process should begin immediately after the vinyl flooring is laid. Start by rolling from the center of the vinyl sheet or tile outwards, working towards the edges. This helps to push out any trapped air and ensure uniform adhesion. Overlap each pass slightly to ensure complete coverage.

Pressure and Speed: Apply consistent pressure while rolling, maintaining a steady pace. Avoid rolling too quickly, as this can prevent the adhesive from making full contact with the subfloor. The amount of pressure required depends on the type of vinyl flooring and the adhesive used. Consulting the manufacturer's instructions is crucial for determining the appropriate pressure.

Seam Sealing: When installing vinyl sheet flooring, proper seam sealing is essential for preventing moisture penetration and ensuring a seamless appearance. Use a seam roller to apply consistent pressure along the seams, creating a tight, waterproof seal. Follow the adhesive manufacturer's instructions for seam sealing techniques.

Cleanliness: Keep the roller clean throughout the installation process. Any adhesive or debris that accumulates on the roller can transfer to the vinyl flooring, creating unsightly marks or interfering with adhesion. Regularly clean the roller with a damp cloth to maintain its effectiveness.

Inspection: After rolling, carefully inspect the vinyl flooring for any bubbles, wrinkles, or other imperfections. Address any issues immediately by re-rolling the affected area or, if necessary, lifting and re-applying the adhesive. Allowing imperfections to remain can lead to more significant problems down the line.

By following these guidelines for proper usage and technique, installers can maximize the effectiveness of the vinyl flooring installation roller and achieve a professional, long-lasting result.

Consequences of Neglecting the Roller: Avoiding Costly Mistakes

Neglecting the use of a vinyl flooring installation roller, or using it improperly, can lead to a range of problems that compromise the integrity and appearance of the floor. These issues can result in costly repairs or even the need for complete replacement, highlighting the importance of this seemingly simple tool.

Air Pockets and Bubbles: The most common consequence of neglecting the roller is the formation of air pockets and bubbles beneath the vinyl flooring. These imperfections not only detract from the aesthetic appeal of the floor but also weaken its structure, making it more susceptible to damage.

Uneven Adhesion: Without consistent pressure applied by the roller, the adhesive may not bond uniformly to the subfloor. This can lead to areas of weak adhesion, where the vinyl flooring is more likely to lift, crack, or become damaged. Uneven adhesion can also create an uneven surface, making the floor uncomfortable to walk on.

Premature Wear and Tear: When vinyl flooring is not properly adhered to the subfloor, it is more susceptible to wear and tear from foot traffic, furniture weight, and other forms of stress. This can lead to premature cracking, tearing, and fading, shortening the lifespan of the floor.

Moisture Damage: Gaps and voids beneath the vinyl flooring can trap moisture, creating a breeding ground for mold and mildew. This can not only damage the floor itself but also pose a health hazard to occupants. Proper rolling helps to seal the edges and prevent moisture from penetrating beneath the vinyl.

Seam Failure: Neglecting to use a seam roller when installing vinyl sheet flooring can lead to seam failure. Improperly sealed seams are prone to moisture penetration, dirt accumulation, and eventual separation, compromising the integrity and appearance of the floor.

Increased Repair Costs: Addressing these issues often involves costly repairs, such as patching damaged areas, re-sealing seams, or even replacing entire sections of the floor. In severe cases, the entire floor may need to be replaced, resulting in significant financial losses.

By understanding the potential consequences of neglecting the vinyl flooring installation roller, installers can appreciate the importance of this tool and take the necessary steps to ensure a successful, long-lasting installation.

Roberts Extendible Floor Roller For Sheet Vinyl Flooring Installation

Rox Vinyl Roller 68 Kg Floorshq

Roberts Extendible Floor Roller For Sheet Vinyl Flooring Installation 10 955 The Home Depot

75 Lb Vinyl And Linoleum Floor Roller Lax Equipment Al

How To Install Vinyl Flooring

Heavy Duty Pvc Vinyl Flooring Installer Linoleum Carpet Sheet Floor Seam Roller Rolling Tool China Made In Com

Roberts Heavy Duty Floor Rollers Contractors Direct

Roberts Extendible Floor Roller For Sheet Vinyl Flooring Installation 10 955 The Home Depot

Roberts Extendible Floor Roller For Sheet Vinyl Flooring Installation 10 955 The Home Depot

75 Lb Vinyl And Linoleum Floor Roller Lax Equipment Al

Related Posts