Vinyl Flooring for Marine Use

Vinyl flooring has become a popular choice for marine applications due to its durability, water resistance, and aesthetic versatility. This flooring option offers a practical and stylish solution for boats, yachts, and other watercraft, providing a comfortable and safe surface for passengers and crew.

Key Benefits of Marine Vinyl Flooring

- Water Resistance

- Durability

- Easy Maintenance

- Comfort

- Safety

- Aesthetic Appeal

- Cost-Effectiveness

The marine environment presents unique challenges for flooring materials. Constant exposure to moisture, saltwater, and UV rays can quickly degrade inferior materials. Vinyl flooring, specifically designed for marine use, is engineered to withstand these harsh conditions. Its inherent water resistance prevents water damage and mold growth, ensuring the longevity of the flooring.

Choosing the Right Marine Vinyl Flooring

- Construction and Thickness

- UV Resistance

- Slip Resistance

- Color and Pattern

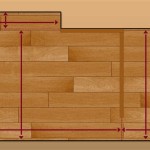

The construction and thickness of marine vinyl flooring play a crucial role in its performance. Multi-layered constructions with a thick wear layer offer superior durability and resistance to punctures and tears. The wear layer, the topmost layer of the flooring, protects against abrasion and foot traffic, maintaining the floor's appearance over time. Selecting a thicker wear layer is recommended for high-traffic areas.

Prolonged exposure to sunlight can cause fading and deterioration in some flooring materials. Choosing marine vinyl flooring with high UV resistance ensures that the color and pattern remain vibrant even after extended periods under the sun. This resistance helps maintain the aesthetic appeal of the vessel's interior.

Safety is paramount in a marine environment. Wet surfaces can pose a significant slipping hazard. Marine vinyl flooring with a textured surface or a non-slip coating provides enhanced traction, reducing the risk of slips and falls. This feature is crucial for ensuring the safety of everyone on board.

Installation of Marine Vinyl Flooring

- Surface Preparation

- Adhesive Selection

- Seaming and Finishing

Proper installation is essential for maximizing the performance and lifespan of marine vinyl flooring. Thorough surface preparation is the first step. The subfloor must be clean, dry, and level to ensure proper adhesion of the flooring. Any imperfections in the subfloor should be addressed before installation to prevent issues later on.

Selecting the correct adhesive is critical for a successful installation. Marine-grade adhesives are designed to withstand the harsh marine environment and provide a strong bond between the flooring and the subfloor. Using the wrong adhesive can lead to premature failure of the flooring installation.

Seaming and finishing require meticulous attention to detail. Seams should be properly sealed to prevent water from penetrating beneath the flooring. Proper finishing techniques ensure a professional and aesthetically pleasing result, contributing to the overall appearance of the vessel's interior.

Maintenance and Care of Marine Vinyl Flooring

- Regular Cleaning

- Stain Removal

- Protecting from UV Exposure

Maintaining the appearance and functionality of marine vinyl flooring requires regular cleaning. Sweeping or vacuuming removes loose dirt and debris, while periodic mopping with a mild detergent and water removes more stubborn dirt and grime. Avoid using harsh chemicals or abrasive cleaners, as these can damage the flooring's surface.

Stains should be addressed promptly to prevent them from setting. Use a damp cloth and a mild cleaning solution to remove stains. For tougher stains, consult the manufacturer's recommendations for appropriate cleaning methods. Avoid using harsh chemicals that could damage the flooring.

While marine vinyl flooring is designed to withstand UV exposure, prolonged exposure can still contribute to fading over time. Using window coverings or boat covers can help protect the flooring from direct sunlight, especially when the vessel is not in use. This preventative measure helps maintain the flooring's vibrant appearance for longer.

Selecting the right marine vinyl flooring involves considering factors like traffic, exposure to the elements, and aesthetic preferences. Consulting with a marine flooring specialist can help ensure the selection of the most appropriate product for the specific application. Proper installation and maintenance are crucial for maximizing the lifespan and performance of marine vinyl flooring, ultimately enhancing the enjoyment and value of the vessel.

Outdoor Marine Vinyl Flooring Premier Collection

Woven Vinyl Options

5 Best Places To Use Vinyl Wrapit Marine

Imo Vinyl And Pvc Or Flooring For Ships Prolance Marine

Woven Vinyl Options

The Best Options Flooring For Your Boat Komodo Luxury

Marine Vinyl Flooring Is All The Rage This Season Matworks

Outdoor Marine Vinyl Flooring Premier Collection

Discover The Best Marine Vinyl Flooring With A Sustainable Touch

Extreme Duty Pontoon Vinyl Flooring

Related Posts