Table Saw Blades for Laminate Flooring: Essential Aspects to Consider

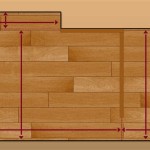

Laminate flooring offers a durable and aesthetically pleasing option for homeowners, but cutting it requires a specialized blade to ensure clean and precise results. Selecting the right table saw blade for laminate flooring is crucial to achieve optimal performance and safety.

Here are some essential aspects to consider when choosing a table saw blade for laminate flooring:

1. Number of Teeth

The number of teeth on the blade affects the smoothness and speed of the cut. Blades with a higher tooth count (80-100) produce smoother cuts but take longer. For laminate flooring, blades with 60-80 teeth offer a good balance between speed and cut quality.

2. Kerf Width

The kerf width refers to the thickness of the cut made by the blade. Narrower kerfs (less than 1/8 inch) reduce material waste and produce cleaner cuts, while wider kerfs can provide faster cutting. For laminate flooring, a kerf width of 1/8 inch or less is ideal.

3. Blade Diameter

The blade diameter determines the maximum depth of cut that the blade can make. Most table saw blades for laminate flooring range from 10 inches to 12 inches in diameter. Larger blades allow for deeper cuts, but they may require more power from the saw.

4. Arbor Size

The arbor size refers to the diameter of the hole in the center of the blade. It must match the arbor size of the table saw to ensure proper fit. Table saw blades for laminate flooring typically have arbor sizes of 5/8 inch or 1 inch.

5. Hook Angle

The hook angle determines the aggressiveness of the cut. Blades with a higher hook angle (10-15 degrees) are more aggressive, cutting faster but leaving a rougher surface. For laminate flooring, a hook angle of 5-10 degrees is recommended for a smooth and clean cut.

6. Carbide Tips

Carbide-tipped blades are highly durable and maintain their sharpness longer than other types of blades. This is particularly important for cutting laminate flooring, as the abrasive nature of the material can quickly dull a blade. Carbide tips extend the blade's life and reduce the need for frequent sharpening.

7. Anti-Kickback Design

Anti-kickback design features on the blade help prevent the workpiece from being thrown back towards the operator during cutting. This is important for safety, especially when working with thin materials like laminate flooring.

8. Manufacturer Reputation

Choosing a reputable manufacturer is equally important. Look for brands with a proven track record of producing high-quality table saw blades for laminate flooring. Reading reviews and researching the manufacturer's experience can help you make an informed decision.

Remember, the optimal blade for your specific application may vary depending on the type of laminate flooring you are cutting and the characteristics of your table saw. It is always advisable to consult with a knowledgeable professional or refer to the manufacturer's recommendations.

Diablo 10in X 12 Teeth Pergoblade Saw Blade For Laminate And Wood Flooring D1012lf The Home Depot

Diablo 10in X 12 Teeth Pergoblade Saw Blade For Laminate And Wood Flooring D1012lf The Home Depot

How To Choose The Right Saw Blade Cut New Flooring Ll

Edge Laminate Circular Saw Blades Bosch Professional

Craftsman 10 In 180 Tooth Fine Finish High Sd Steel Miter Table Saw Blade The Circular Blades Department At Com

Diablo 7 1 4in X 8 Teeth Pergoblade Saw Blade For Laminate And Wood Flooring D0708lf The Home Depot

The Best Saw Blade For Cutting Laminate Flooring Bob Vila

Top 5 Best Saw Blade For Laminate Flooring 2024

How To Cut Laminate Flooring Maun Industries Limited

The Best Saw Blade For Cutting Laminate Flooring Bob Vila

Related Posts