Choosing the Right Saw for Laminate Flooring

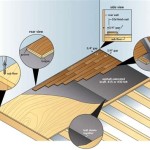

Laminate flooring, a popular alternative to hardwood, offers durability, affordability, and aesthetic appeal. Its layered construction, typically consisting of a wear layer, a decorative layer, a core board (often high-density fiberboard or HDF), and a balancing layer, necessitates a specific approach to cutting. Selecting the appropriate saw is crucial for achieving clean, chip-free cuts that contribute to a professional-looking installation. The wrong tool can lead to splintering, uneven edges, and ultimately, a less-than-satisfactory finished product.

The market presents a variety of saw options, each with its own strengths and weaknesses when applied to laminate flooring. Understanding these nuances allows installers, both professional and DIY, to make informed decisions based on the project's scale, complexity, and budget. This article will explore several types of saws commonly used for cutting laminate flooring, highlighting their suitability and offering guidance on choosing the optimal tool.

Circular Saws: Power and Efficiency

Circular saws are a ubiquitous power tool, prized for their speed and ability to make long, straight cuts. When used correctly, they can be effective for cutting laminate flooring, particularly in larger projects where numerous planks need to be processed quickly. However, their aggressive cutting action can also lead to significant chipping and splintering, especially on the visible wear layer. Mitigating this risk requires careful technique and the use of specialized blades.

The key to successful laminate cutting with a circular saw lies in selecting a blade designed specifically for this purpose. Look for blades with a high tooth count (typically 60 teeth or more) and a triple-chip grind (TCG) or modified triple-chip grind (MTCG) tooth geometry. These blade designs are engineered to shear the laminate cleanly, reducing the likelihood of chipping. The tooth arrangement effectively scores the surface before the main cutting action takes place, resulting in a smoother edge. Furthermore, carbide-tipped blades are essential for longevity, as they resist wear when cutting through the dense HDF core of laminate flooring.

Beyond the blade, proper technique is paramount. Always cut with the finished side of the laminate facing up. This way, any chipping that does occur will be on the underside of the plank, which will be concealed after installation. Using painter's tape along the cut line can also help to minimize splintering. The tape provides additional support to the surface and prevents the blade from lifting the fragile wear layer. Before making the full cut, consider scoring the cut line with a utility knife. This creates a preliminary channel that further reduces the risk of chipping.

Finally, a stable work surface is crucial. Secure the laminate plank firmly to a workbench or sawhorse setup to prevent it from vibrating during the cutting process. This ensures accurate and consistent cuts. Furthermore, consider using a saw guide or straight edge to maintain a perfectly straight cutting path. Freehand cuts with a circular saw can easily deviate, leading to uneven edges and wasted material.

Jigsaws: Versatility for Curves and Intricate Cuts

Jigsaws offer a different approach to cutting laminate flooring, prioritizing versatility over sheer speed. While they may not be the ideal choice for long, straight cuts, jigsaws excel at creating curves, notches, and other irregular shapes. This makes them indispensable for fitting laminate flooring around obstacles such as pipes, door frames, and transitions.

Similar to circular saws, the blade selection is critical for achieving clean cuts with a jigsaw. Blades specifically designed for laminate or fine-tooth blades intended for wood are recommended. Look for blades with an upward-cutting action, as these tend to produce cleaner edges on the visible surface of the laminate. Downward-cutting blades, while sometimes used, can pull the laminate upward, leading to chipping.

The jigsaw's orbital action, which refers to the blade's elliptical movement, can be adjusted to suit the material being cut. For laminate flooring, a minimal or no orbital action is generally preferred. This reduces the aggressiveness of the cut and minimizes the risk of splintering. The jigsaw's speed should also be carefully controlled. A slower speed allows for greater precision and reduces heat buildup, which can contribute to chipping.

When cutting curves or intricate shapes, a sharp, thin jigsaw blade is essential. A dull blade will wander, resulting in inaccurate cuts. Using a blade with a narrow profile allows for tighter curves and more intricate designs. Furthermore, applying a lubricant, such as wax or cutting fluid, to the blade can help to reduce friction and heat, resulting in cleaner cuts and extending the blade's lifespan.

Supporting the laminate plank properly is crucial when using a jigsaw. The workpiece should be firmly clamped to a stable surface to prevent it from vibrating or shifting during the cutting process. This is particularly important when cutting curves, as any movement can lead to inaccuracies. Follow the cut line carefully, avoiding excessive pressure on the saw. Let the blade do the work, guiding it smoothly along the desired path.

Laminate Flooring Cutters: Specialized Tools for Straight Cuts

Laminate flooring cutters, also known as guillotine cutters or simply laminate cutters, are specialized tools designed specifically for cutting laminate planks. These cutters utilize a long, sharp blade that shears the laminate in a single, clean pass. They offer several advantages over power saws, including dust-free operation, quietness, and ease of use. Furthermore, they eliminate the risk of chipping and splintering, provided they are properly maintained and used correctly.

The primary advantage of a laminate flooring cutter is its ability to produce clean, straight cuts without the noise and dust associated with power saws. This makes it an ideal choice for indoor projects where noise levels need to be minimized and dust control is a concern. The cutting action is relatively simple: the laminate plank is placed on the cutter's base, aligned with the desired cut line, and the blade is brought down using a lever or handle. The blade shears the laminate cleanly, leaving a smooth, chip-free edge.

While laminate flooring cutters excel at making straight cuts, they are not well-suited for cutting curves or intricate shapes. Their primary limitation is their blade design, which is optimized for straight-line shearing. Therefore, they are typically used in conjunction with other tools, such as jigsaws, for handling more complex cuts.

The effectiveness of a laminate flooring cutter depends on the quality and sharpness of its blade. A dull blade will require more force to operate and may result in crushed or uneven edges. Regularly sharpening or replacing the blade is essential for maintaining optimal performance. Furthermore, it is important to choose a cutter that is appropriately sized for the thickness and width of the laminate planks being used. Overloading the cutter can damage the blade or the cutter itself.

Operating a laminate flooring cutter requires minimal training. The plank is positioned against the fence, and the cutting arm is brought down firmly. Ensure the laminate is securely positioned before initiating the cut to prevent movement and ensure a clean, accurate cut. Always wear safety glasses to protect your eyes from debris.

Hand Saws: Traditional Precision and Control

While power tools offer speed and efficiency, hand saws retain their relevance for certain laminate flooring applications. Hand saws provide a level of control and precision that is difficult to achieve with power tools, particularly when making small adjustments or delicate cuts. They are also a viable option for projects where power is not readily available or where noise is a concern.

When selecting a hand saw for laminate flooring, a fine-tooth saw is essential. A traditional crosscut saw with a high tooth count (typically 12-14 teeth per inch) will produce cleaner cuts than a coarser rip saw. A Japanese pull saw, also known as a dozuki saw, is another excellent option. These saws feature a thin, flexible blade and very fine teeth, making them ideal for cutting laminate with minimal chipping. The pull stroke cutting action also contributes to greater control and precision.

Using a hand saw effectively requires patience and technique. Secure the laminate plank firmly to a workbench or sawhorse setup. Draw a clear, accurate cut line using a straight edge and a sharp pencil. Start the cut by gently scoring the surface of the laminate along the cut line. This helps to prevent chipping and provides a guide for the saw blade. Apply consistent pressure and maintain a steady sawing motion, following the cut line carefully.

Hand saws are particularly useful for making small adjustments or trimming planks to fit precisely against walls or other obstacles. They provide a more controlled and delicate cutting action than power saws, reducing the risk of overcutting or damaging the laminate. Furthermore, they are a quieter alternative to power saws, making them suitable for use in noise-sensitive environments.

Maintaining a sharp hand saw is crucial for achieving clean, accurate cuts. A dull saw will require more force to operate and may result in jagged or uneven edges. Regularly sharpening the saw teeth or replacing the blade is essential for optimal performance. A well-maintained hand saw can be a valuable tool for any laminate flooring project, providing precision and control when needed.

Ultimately, choosing the right saw for laminate flooring depends on the specific requirements of the project. Considering the factors such as the project's size, the complexity of the cuts, the desired level of precision, and the budget is crucial for making an informed decision. Each saw type offers its own unique set of advantages and disadvantages, and the best approach often involves using a combination of tools to achieve the desired results.

What Is The Best Saw For Cutting Laminate Flooring Quora

How To Cut Laminate Flooring Lv Hardwood Toronto

How To Cut Laminate Flooring Maun Industries Limited

How To Saw Or Cut Laminate Flooring Tutorial By Quick Step

How To Cut Laminate Flooring Best

Laminate Flooring Tools For Installing

How To Cut Laminate Flooring A Complete Diy Guide

Top 5 Best Saw To Cut Laminate Flooring In 2024

Ryobi Pgc21b Circular Saw Review Best Saws 2024

Bosch Jigsaw Dan Pattison Blog

Related Posts