Rough Sawn Engineered Oak Flooring: A Comprehensive Guide

Rough sawn engineered oak flooring represents a unique blend of rustic charm and modern engineering. It combines the aesthetic appeal of solid hardwood with the enhanced stability and versatility of engineered construction. This flooring option is becoming increasingly popular for homeowners and designers seeking a distinctive and durable surface that adds character to any space.

Understanding the nuances of rough sawn engineered oak flooring involves considering its construction, aesthetic qualities, performance characteristics, and maintenance requirements. This article aims to provide a comprehensive overview, allowing readers to make informed decisions about whether this flooring type is suitable for their specific needs and preferences.

Engineered flooring, in general, is constructed from multiple layers of wood bonded together. The top layer, known as the wear layer, is made of solid hardwood. In the case of rough sawn engineered oak flooring, this wear layer is crafted from oak and treated to create a textured, rustic appearance. The underlying layers typically consist of plywood, high-density fiberboard (HDF), or softwood, which are arranged in a cross-grain pattern to enhance dimensional stability and resistance to warping and expansion.

The rough sawn texture is achieved through various milling techniques that leave the surface with saw marks, imperfections, and a generally uneven feel. This deliberate roughness contributes to the floor's character and differentiates it from smoother, more refined hardwood options. The process often involves using specialized blades or manipulating the milling process to accentuate the wood's natural grain and imperfections.

Oak, a widely used hardwood in flooring, is prized for its durability, strength, and attractive grain patterns. It is also relatively abundant and readily available, making it a cost-effective choice compared to some other hardwood species. The species of oak used for the wear layer can vary, including white oak and red oak, each offering slightly different aesthetic characteristics and hardness ratings.

Key Point 1: Construction and Stability

The engineered construction of the flooring plays a crucial role in its performance and longevity. The cross-grain construction of the core layers minimizes the wood's natural tendency to expand and contract with changes in humidity and temperature. This makes engineered flooring a more dimensionally stable option compared to solid hardwood, particularly in environments with fluctuating moisture levels, such as basements or homes in humid climates.

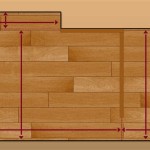

The thickness of the wear layer is a critical factor influencing the lifespan and refinishing potential of the flooring. A thicker wear layer allows for more sanding and refinishing cycles, extending the floor's overall life. Generally, a wear layer of 2mm or more is considered suitable for residential use, while thicker wear layers, such as 4mm or 6mm, are preferred for high-traffic areas or commercial applications.

The quality of the adhesive used to bond the layers together is also paramount. High-quality adhesives ensure a strong and lasting bond, preventing delamination and ensuring the floor's structural integrity. Reputable manufacturers typically use specialized adhesives engineered for wood flooring applications.

The stability provided by the engineered construction allows for installation over a wider range of subfloors, including concrete slabs and existing flooring. This versatility makes it a popular choice for renovations and new construction projects alike. It also allows for various installation methods, such as gluing, nailing, or floating, depending on the specific product and subfloor conditions.

The dimensional stability of rough sawn engineered oak flooring also reduces the risk of gapping between planks, which can be a common issue with solid hardwood floors in fluctuating environments. This helps to maintain a consistent and aesthetically pleasing appearance over time.

Key Point 2: Aesthetic Appeal and Design Versatility

The primary appeal of rough sawn engineered oak flooring lies in its rustic and character-rich aesthetic. The saw marks and imperfections on the surface create a visually interesting texture that adds depth and warmth to any room. This flooring type is often chosen to create a farmhouse, industrial, or vintage-inspired look.

The natural grain patterns of the oak wood are accentuated by the rough sawn texture, highlighting the wood's unique character and beauty. Knot holes, mineral streaks, and other natural variations are often incorporated into the design to enhance the rustic appeal of the flooring.

The flooring is available in a wide range of colors and finishes, allowing homeowners and designers to customize the look to suit their specific design preferences. Light stains can enhance the natural beauty of the oak, while darker stains can create a more dramatic and sophisticated look. Wire brushing and distressing techniques are also often employed to further enhance the rustic texture and character of the flooring.

The wider planks often associated with this type of flooring contribute to a more spacious and luxurious feel. Wider planks also showcase more of the wood's natural grain patterns, adding to the overall aesthetic appeal.

Because each plank exhibits unique variations in texture and grain, rough sawn engineered oak flooring creates a one-of-a-kind look that cannot be replicated with synthetic flooring options. This individuality adds value and character to any space.

Key Point 3: Maintenance and Durability

While rough sawn engineered oak flooring offers a unique aesthetic, its maintenance requirements should be considered carefully. The textured surface can trap dirt and debris more easily than smoother flooring options. Regular sweeping or vacuuming is essential to prevent the buildup of dust and grime.

Mopping should be done with a damp mop and a pH-neutral wood floor cleaner. Excessive moisture should be avoided, as it can damage the wood and cause warping or swelling. It is also important to avoid using abrasive cleaners or scouring pads, as these can scratch the surface and damage the finish.

The durability of the flooring is largely dependent on the thickness of the wear layer and the quality of the finish. A thicker wear layer provides more protection against scratches and dents, while a durable finish helps to resist wear and tear. Polyurethane finishes are a popular choice for engineered oak flooring due to their durability and water resistance. Oil-based finishes are also available and offer a more natural look and feel, but may require more frequent maintenance.

Despite its rustic appearance, rough sawn engineered oak flooring can be surprisingly durable. The engineered construction provides enhanced stability, while the oak wear layer offers resistance to scratches and dents. However, it is still important to take precautions to protect the flooring from damage. Using furniture pads under heavy objects can help to prevent scratches, and placing mats at entryways can help to trap dirt and debris before they are tracked onto the floor.

Regular maintenance and proper care can help to extend the lifespan of rough sawn engineered oak flooring and maintain its beauty for many years to come. Refinishing is also an option, depending on the thickness of the wear layer, allowing the floor to be restored to its original condition or even transformed with a new stain or finish.

In conclusion, rough sawn engineered oak flooring presents a compelling option for those seeking a flooring solution that combines aesthetic appeal with practical benefits. Its engineered construction provides stability and versatility, while its rustic texture adds character and warmth to any space. Careful consideration of its construction, design potential, and maintenance requirements will ensure a satisfactory and long-lasting flooring investment.

Chepstow Sawn Grey Oak Engineered Wood Flooring

Wide Plank Rustic Hardwood Flooring Gaylord

170mm Engineered Rough Sawn Flooring Earthwood Floors

Rough Sawn Boardwalk Hardwood Floors

170mm Engineered Rough Sawn Flooring Earthwood Floors

Wide Plank Rustic Hardwood Flooring Gaylord

Our Remarkable Rough Sawn Engineered Wood Floor Country Oak Floors Flooring

Wide Plank Rustic Hardwood Flooring Gaylord

Band Sawn Classic Grade European Oak Flooring

Engineered Oak Flooring Vastern

Related Posts