Locking Wood Flooring: Essential Aspects to Ensure a Durable and Aesthetic Installation

Locking wood flooring, also known as floating flooring, has gained immense popularity due to its ease of installation, durability, and aesthetic appeal. Unlike traditional wood flooring that requires nails or adhesives, locking wood flooring features interlocking planks that fit together seamlessly. Understanding the essential aspects of locking wood flooring is crucial for a successful and long-lasting installation.

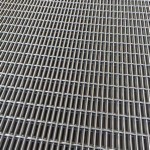

Plank Construction: Locking wood flooring planks are typically made of a durable core material, such as high-density fiberboard (HDF) or engineered wood, with a decorative top layer of real wood or laminate. The interlocking system consists of ridges and grooves along the edges of the planks. The ridges of one plank fit into the grooves of the adjacent plank, creating a strong and secure connection.

Locking Mechanisms: There are several different locking mechanisms available in locking wood flooring. Some of the most common include:

- Click Lock: Click lock systems feature a tongue-and-groove design with a locking bar. As the planks are pushed together, the locking bar engages and clicks into place, securing the planks.

- Unilin Click: Unilin Click is a specific type of click lock system that is known for its high-precision fit and strong hold.

- Fold Down Lock: Fold down lock systems have a flexible tab that folds down over the edge of the adjacent plank, creating a tight and durable connection.

Preparation: Before installing locking wood flooring, it is essential to prepare the subfloor thoroughly. The subfloor should be level, dry, and in good condition. Any uneven areas or imperfections should be addressed to prevent issues with the flooring installation.

Installation: Locking wood flooring is installed in a floating manner, which means it does not attach directly to the subfloor. Instead, it is held in place by the interlocking connections between the planks. The installation process typically involves starting at one corner of the room and working your way across, locking each plank into the next until the floor is complete.

Maintenance: Locking wood flooring requires minimal maintenance to keep it looking its best. Regular sweeping and vacuuming will remove dirt and dust. Spills should be wiped up promptly to prevent staining. It is also important to avoid using harsh chemicals or abrasive cleaners, as they can damage the flooring.

Unlocking The Benefits Of Locking Hardwood Floors

How To Fit Engineered Flooring With Locking System Blog Floorsave

Lock Glueless Hardwood Flooring

Locking Type Plank Soft Wooden False Flooring Size Dimension 8 Inch 48 Thickness 9mm At Rs 75 Sq Ft In Surat

How To Install Lock Engineered Hardwood Flooring

Floor Locking Technology Lock Over Tongue Groove Mikasa Floors

Lock Glueless Hardwood Flooring

Wood Wax Oiled European Oak Engineerd Floor Locking Floating System China Engineered Made In Com

Modern Wood Floor Tile Locking Water Resistente Plank Flooring Clearhalo

Locking Hardwood At Com

Related Posts