Laminate Panels Flooring: A Comprehensive Guide

Laminate panels flooring has emerged as a popular and versatile flooring option for residential and commercial spaces. Its affordability, durability, and aesthetic appeal contribute to its widespread adoption. This article explores the characteristics, advantages, installation, maintenance, and considerations associated with laminate panels flooring.

Understanding Laminate Composition and Manufacturing

Laminate flooring comprises several layers bonded together under high pressure. Understanding these layers is crucial for appreciating the product's performance characteristics. The typical composition includes a wear layer, a decorative layer, a core layer, and a backing layer.

The wear layer, the topmost layer, is a transparent coating that protects the floor from scratches, stains, and fading. It is typically made of aluminum oxide or melamine resin, with varying thicknesses that determine the floor's resistance to wear and tear. A thicker wear layer generally signifies better durability and longer lifespan, making it suitable for high-traffic areas.

Beneath the wear layer lies the decorative layer, a high-resolution photographic image that replicates the appearance of natural wood, stone, or tile. Advanced printing technology allows for a wide variety of realistic textures and patterns, enabling consumers to achieve the desired aesthetic without the cost and maintenance associated with natural materials. The quality of the decorative layer significantly impacts the overall visual appeal of the laminate flooring.

The core layer, usually made of high-density fiberboard (HDF) or medium-density fiberboard (MDF), provides the structural integrity and stability of the laminate panel. HDF is denser and more resistant to moisture than MDF, making it a preferred choice for areas prone to humidity. The thickness and density of the core layer influence the floor's resistance to impact, indentation, and warping.

The backing layer, the bottommost layer, provides a moisture barrier and balances the panel, preventing it from cupping or bowing. It is typically made of melamine resin or a similar material. The backing layer contributes to the overall stability and longevity of the laminate flooring.

The manufacturing process involves bonding these layers together under intense heat and pressure. This process creates a strong and durable panel that is resistant to wear, stains, and fading. The quality control measures implemented during manufacturing are critical to ensuring the consistency and performance of the finished product.

Advantages of Laminate Panels Flooring

Laminate flooring offers numerous advantages compared to other flooring options, contributing to its increasing popularity. These advantages include affordability, durability, ease of installation, maintenance, and design versatility.

Cost-effectiveness is a primary driver for choosing laminate flooring. It is significantly less expensive than natural hardwood, stone, or tile, making it an attractive option for budget-conscious consumers. The lower material and installation costs allow homeowners to achieve the desired aesthetic without breaking the bank.

Durability is another key advantage. The wear layer protects the floor from scratches, stains, and fading, making it suitable for high-traffic areas and households with children and pets. Laminate flooring is also resistant to impact and indentation, ensuring that it maintains its appearance over time. The AC (Abrasion Class) rating system indicates the floor's resistance to wear, with higher AC ratings signifying greater durability.

Ease of installation is a significant benefit for both DIY enthusiasts and professional installers. Most laminate flooring systems feature a click-lock mechanism that allows the panels to be easily connected without the need for glue or nails. This simplifies the installation process and reduces labor costs. The floating floor installation method also allows laminate flooring to be installed over existing subfloors, saving time and effort.

Maintenance is relatively simple. Regular sweeping or vacuuming is sufficient to remove dirt and debris. Occasional damp mopping with a mild detergent keeps the floor clean and shiny. Laminate flooring is also resistant to stains and spills, making it easy to clean up messes quickly. Avoid using abrasive cleaners or excessive water, as these can damage the floor.

Design versatility is a major selling point. Laminate flooring is available in a wide variety of colors, patterns, and textures, replicating the look of natural wood, stone, or tile. This allows consumers to achieve the desired aesthetic without the cost and maintenance associated with natural materials. The variety of edge profiles and plank sizes further enhances the design options.

Installation Considerations and Best Practices

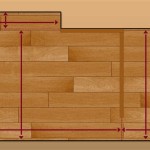

Proper installation is crucial for ensuring the long-term performance and appearance of laminate flooring. Careful preparation, appropriate tools, and adherence to best practices are essential for a successful installation. Key considerations include subfloor preparation, acclimation, moisture testing, and expansion gaps.

Subfloor preparation is paramount. The subfloor must be clean, level, and dry before installing laminate flooring. Any imperfections, such as cracks or unevenness, must be addressed to prevent problems with the finished floor. Concrete subfloors should be tested for moisture content to ensure that it is within acceptable limits. Wood subfloors should be inspected for damage and repaired as needed. A level subfloor ensures that the laminate panels sit properly and prevents uneven wear or damage.

Acclimation is essential for allowing the laminate flooring to adjust to the room's temperature and humidity. The panels should be stored in the room where they will be installed for at least 48 to 72 hours before installation. This allows the panels to expand or contract, minimizing the risk of gaps or buckling after installation. Follow the manufacturer's recommendations for acclimation.

Moisture testing is particularly important for concrete subfloors. Excessive moisture can cause the laminate flooring to warp or buckle. A moisture meter can be used to determine the moisture content of the concrete subfloor. If the moisture level is too high, a moisture barrier should be installed before laying the laminate flooring. Proper ventilation and humidity control can also help prevent moisture-related problems.

Expansion gaps are necessary to allow the laminate flooring to expand and contract with changes in temperature and humidity. A gap of approximately ¼ inch should be left around the perimeter of the room and around any fixed objects, such as pipes or cabinets. These gaps should be covered with baseboards or moldings to conceal them and provide a finished look. Failure to provide adequate expansion gaps can result in buckling or lifting of the flooring.

When installing the laminate panels, follow the manufacturer's instructions carefully. Use appropriate tools, such as a tapping block and pull bar, to ensure that the panels are properly connected. Stagger the end joints of the panels to create a more visually appealing and structurally sound floor. Avoid using excessive force when connecting the panels, as this can damage the locking mechanism.

For complicated installations, such as around doorways or corners, consider using a professional installer. A professional installer has the experience and expertise to ensure that the laminate flooring is installed correctly and efficiently. This can save time and effort and prevent costly mistakes.

After installation, inspect the floor carefully for any gaps or imperfections. Repair any issues promptly to prevent further damage. Protect the floor with felt pads under furniture legs to prevent scratches and dents. With proper installation and maintenance, laminate flooring can provide years of beauty and durability.

The selection of appropriate underlayment is also significant during installation. Underlayment provides cushioning, reduces noise transmission, and offers additional moisture protection. Various types of underlayment are available, each with its own benefits and drawbacks. Choose an underlayment that is compatible with the laminate flooring and meets the specific needs of the installation.

Consider the direction of the laminate panels during installation. Generally, running the panels parallel to the longest wall of the room can make the space appear larger. However, the direction can also be influenced by the location of windows and the direction of natural light. Experiment with different layouts to determine the best option for the space.

Pay attention to the details, such as the transition strips between different types of flooring or rooms. Use transition strips that are compatible with the laminate flooring and provide a smooth and seamless transition. These strips enhance the appearance of the floor and prevent tripping hazards.

Laminate Flooring Panel At Rs 65 Sq Ft In Srinagar Id 2850732090712

Laminate Flooring Types And S Forbes Home

Green Panel Wooden Flooring Thickness 8 3 Mm At Rs 95 Sq Ft In New Delhi Id 2850957056088

Waterproof Wooden Laminate Flooring For Residential At Rs 140 Sq Ft In Mysore

Aeden Exhibition Brown Laminated Panel For Commercial Thickness Standard At Rs 950 Sheet In New Delhi

D Spaze Oak Wood Laminate Flooring Panel For Home Thickness 8 Mm At Rs 80 Sq Ft In New Delhi

Laminated Wooden Flooring Panel For Home Hotel And Office At Rs 95 Square Feet In Sas Nagar

Laminate Vs Hardwood Flooring Major Differences Forbes Home

Greenpanel Wood Floors Luxury Flooring Plywood

Laminated Wooden Flooring Latest Manufacturer In Jaipur

Related Posts