Laminate Flooring With Attached Underlayment: An In-Depth Guide

Laminate flooring has become a popular choice for homeowners and businesses alike due to its durability, affordability, and aesthetic versatility. One variation that has gained significant traction is laminate flooring with attached underlayment. This type of flooring combines the visual appeal of laminate with the added convenience and benefits of a built-in underlayment. This article provides a comprehensive overview of laminate flooring with attached underlayment, covering its advantages, disadvantages, installation considerations, and maintenance procedures.

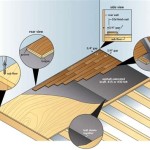

Laminate flooring, in its basic form, is a multi-layered synthetic flooring product. It typically consists of four layers: a wear layer, a decorative layer, a core layer, and a backing layer. The wear layer, usually made of aluminum oxide, provides resistance against scratches, stains, and fading. The decorative layer is a high-resolution photographic image that mimics the appearance of wood, stone, or tile. The core layer, often made of high-density fiberboard (HDF) or medium-density fiberboard (MDF), provides stability and impact resistance. The backing layer provides balance and helps prevent moisture from penetrating the core.

Underlayment, typically a thin layer of foam, cork, or felt, is installed between the subfloor and the flooring material. It serves several critical functions, including cushioning, sound insulation, and moisture barrier. Traditionally, underlayment is installed as a separate layer before the laminate flooring is laid. However, laminate flooring with attached underlayment streamlines this process by integrating the underlayment directly onto the back of the laminate planks or tiles.

The integration of the underlayment represents a significant advancement in flooring technology, offering numerous benefits in terms of installation efficiency and overall performance.

Key Advantages of Laminate Flooring with Attached Underlayment

The primary appeal of laminate flooring with attached underlayment lies in its practical benefits, which contribute to ease of installation, enhanced performance, and long-term cost savings.

Simplified Installation: One of the most significant advantages is the reduced installation time and complexity. Because the underlayment is pre-attached, there is no need to purchase and install a separate underlayment layer. This saves time, labor costs, and reduces the potential for errors during installation. For DIY enthusiasts, this simplifies the project considerably, making it more accessible and less daunting. Furthermore, it ensures that the underlayment is properly aligned and secured, eliminating common issues such as wrinkling or shifting that can occur with separate underlayment layers. This is especially beneficial on larger flooring projects where consistent and efficient installation is paramount.

Improved Sound Insulation: The attached underlayment significantly improves sound absorption and reduces noise transmission. This is particularly important in multi-story homes or apartments where minimizing noise is crucial. The underlayment acts as a barrier, absorbing impact sounds and preventing them from traveling to rooms below. This can create a quieter and more comfortable living environment. The level of sound insulation can vary depending on the type and thickness of the attached underlayment. Typically, denser and thicker underlayment materials provide better sound reduction. Manufacturers often provide an Impact Insulation Class (IIC) rating for their products, which indicates the level of sound isolation achieved.

Enhanced Comfort: The attached underlayment provides added cushioning underfoot, making the floor more comfortable to walk on. This is especially noticeable compared to laminate flooring installed directly over a hard subfloor. The cushioning effect can reduce fatigue and improve the overall comfort of the living space. This is particularly beneficial in areas where people spend a lot of time standing, such as kitchens or home offices. The added comfort can also be an advantage for individuals with joint pain or other mobility issues.

Moisture Barrier Properties: Many attached underlayments are designed with moisture barrier properties, which help protect the laminate core from moisture damage. This is especially important in areas with high humidity or where spills are likely to occur, such as kitchens and bathrooms. The moisture barrier helps prevent the laminate from warping, swelling, or developing mold and mildew. While the attached underlayment provides a degree of moisture protection, it is still essential to address any underlying moisture issues in the subfloor before installation. Proper vapor barriers may still be necessary in certain situations, especially when installing over concrete slabs.

Cost-Effectiveness: While the initial cost of laminate flooring with attached underlayment might be slightly higher than standard laminate flooring, the overall cost can be lower due to the elimination of the separate underlayment purchase and installation costs. This can result in significant savings, especially for larger projects. Furthermore, the simplified installation process can reduce labor costs, making it an economically attractive option for both homeowners and contractors.

Potential Drawbacks and Considerations

Despite the numerous advantages, it is essential to acknowledge the potential drawbacks and considerations associated with laminate flooring with attached underlayment.

Limited Underlayment Options: Because the underlayment is pre-attached, the homeowner has limited control over the type and thickness of the underlayment. This can be a disadvantage if specific underlayment properties, such as superior sound insulation or enhanced moisture protection, are required. In situations where specialized underlayment is needed, standard laminate flooring with a separate underlayment layer might be a better choice. For example, if installing over a particularly uneven subfloor, a thicker underlayment with self-leveling properties might be necessary.

Thickness Considerations: The attached underlayment adds to the overall thickness of the flooring. This can be a concern in areas with low ceilings or where the flooring needs to transition seamlessly with existing flooring. It is crucial to consider the total thickness of the flooring, including the attached underlayment, when planning the installation. Failure to do so can result in uneven transitions, door clearance issues, or aesthetic inconsistencies. In some cases, trimming doors or adjusting thresholds might be necessary to accommodate the added thickness.

Repair Challenges: If a section of the flooring is damaged, repairing it can be more challenging compared to standard laminate flooring. Because the underlayment is attached, replacing a single plank or tile might require removing a larger section of the flooring. This can be more time-consuming and potentially more costly. However, proper maintenance and care can minimize the likelihood of damage and extend the lifespan of the flooring.

Subfloor Preparation: While the attached underlayment can provide some cushioning and compensate for minor imperfections in the subfloor, proper subfloor preparation is still essential. The subfloor needs to be clean, level, and dry before installing the laminate flooring. Any significant unevenness or damage should be addressed before installation to ensure a stable and long-lasting flooring surface. Failure to properly prepare the subfloor can result in issues such as squeaking, buckling, or premature wear.

Cost: While, as previously discussed, savings can be realised during the installation phase, the initial cost of purchase for laminate flooring with attached underlayment may be higher when compared with the alternative. This is a factor to consider where budgetary constraints are more pressing.

Installation and Maintenance

Proper installation and maintenance are crucial for maximizing the lifespan and performance of laminate flooring with attached underlayment.

Installation: The installation process for laminate flooring with attached underlayment is generally straightforward, especially for those familiar with click-lock flooring systems. However, it is essential to follow the manufacturer's instructions carefully. Start by ensuring the subfloor is clean, level, and dry. Acclimate the flooring to the room's temperature and humidity for at least 48 hours before installation. This allows the flooring to expand or contract, preventing issues after installation. When laying the flooring, use spacers to maintain a consistent expansion gap around the perimeter of the room. This allows for natural movement of the flooring due to changes in temperature and humidity. Use a tapping block and hammer to gently lock the planks or tiles together. Avoid using excessive force, which can damage the locking mechanisms. After installation, remove the spacers and install baseboards or quarter-round molding to cover the expansion gap.

Maintenance: Maintaining laminate flooring with attached underlayment is relatively simple. Regular sweeping or vacuuming is essential to remove dirt and debris. Use a damp mop with a mild detergent specifically designed for laminate floors to clean the flooring. Avoid using excessive water, which can seep into the seams and damage the core. Wipe up spills immediately to prevent staining or moisture damage. Avoid using abrasive cleaners, scouring pads, or wax-based products, which can damage the wear layer. Place mats or rugs in high-traffic areas to protect the flooring from scratches and wear. Use furniture pads under the legs of furniture to prevent dents and scratches. Avoid wearing shoes with hard soles or high heels on the flooring. With proper care and maintenance, laminate flooring with attached underlayment can provide years of beauty and performance.

In summary, laminate flooring with attached underlayment offers a compelling combination of convenience, performance, and cost-effectiveness. Its simplified installation, improved sound insulation, enhanced comfort, and moisture barrier properties make it a desirable option for a variety of applications. However, it is essential to consider the potential drawbacks, such as limited underlayment options and thickness considerations, before making a decision. With proper installation and maintenance, this type of flooring can provide a durable and aesthetically pleasing flooring solution for many years to come.

The 6 Best Waterproof Laminate Flooring Brands Of 2024 Floorings

Laminate Flooring With Attached Underlayment Pros And Cons Mp Global S Llc

Laminate Flooring With Attached Underlayment

Laminate Flooring With Pad Underlayment Waterproof Floor Decor

Attached Pad Laminate Flooring At Com

What Should I Look For In Laminate Flooring Underlayment

Spc Flooring Tile Vinyl Rigid Core Plank With Attached Pad China Floor Made In Com

Laminate Flooring Plank With Attached Underlayment

Underlayment Buyer S Guide

Attached Pad Laminate Flooring At Com

Related Posts