Installing Wood Flooring On a Cement Slab: A Comprehensive Guide

Installing wood flooring over a cement slab can significantly enhance the aesthetic appeal and comfort of a room. However, unlike installing wood flooring over a wood subfloor, installing over concrete requires careful preparation and specific techniques to address potential moisture issues and ensure a long-lasting, stable floor. This article provides a detailed guide to successfully installing wood flooring on a cement slab, covering essential steps from preparation to installation.

The success of any wood flooring installation on concrete hinges on understanding the unique challenges presented by concrete. Concrete is porous and can wick moisture from the ground. This moisture can lead to warping, buckling, and mold growth in the wood flooring if not properly addressed. Therefore, thorough moisture testing and the implementation of a suitable moisture barrier are paramount.

Key Point 1: Moisture Testing and Mitigation

Before commencing any wood flooring installation, it is imperative to conduct moisture tests on the concrete slab. These tests will determine the moisture content of the slab and inform the selection of appropriate moisture mitigation methods. There are several methods for testing moisture levels in concrete, each with its own advantages and limitations. The choice of method depends on the specific project requirements and budget.

One commonly used method is the calcium chloride test (also known as the anhydrous calcium chloride test). This test involves placing a measured amount of calcium chloride under a sealed dome on the concrete surface for a specific period. The calcium chloride absorbs moisture from the concrete, and the weight gain is used to calculate the moisture emission rate. This rate is typically expressed in pounds of moisture emitted per 1,000 square feet over 24 hours (lbs/1000 sq ft/24 hrs). Manufacturers of wood flooring products usually specify maximum allowable moisture emission rates for their products. If the test results exceed these limits, moisture mitigation is required.

Another method involves using electronic moisture meters. These meters use electrical conductivity or capacitance to estimate the moisture content of the concrete. While easier and faster to use than the calcium chloride test, electronic meters provide relative moisture readings rather than precise measurements. They should be used in conjunction with other testing methods for a more accurate assessment.

Once the moisture test results are obtained, appropriate mitigation measures can be implemented. The choice of mitigation method depends on the severity of the moisture problem. For relatively minor moisture issues, a simple vapor retarder membrane may suffice. This membrane is typically a polyethylene film that is installed between the concrete slab and the wood flooring.

For more severe moisture problems, more robust solutions are required. These solutions may include applying a liquid epoxy moisture barrier or installing a subfloor system with built-in vapor barriers. Liquid epoxy moisture barriers are applied directly to the concrete surface and create a seamless, impermeable layer that prevents moisture from migrating into the wood flooring. Subfloor systems with vapor barriers typically consist of interlocking panels or sleepers that are raised off the concrete surface, creating an air gap that allows for ventilation and moisture evaporation.

Regardless of the moisture mitigation method chosen, it is crucial to follow the manufacturer's instructions carefully to ensure proper installation and effectiveness. Failure to properly address moisture issues can lead to costly problems down the line.

Key Point 2: Choosing the Right Wood Flooring and Installation Method

The type of wood flooring selected and the installation method employed are critical factors that influence the success of a wood flooring installation on concrete. Solid hardwood flooring is generally not recommended for direct installation over concrete slabs, particularly in areas with high moisture levels. Solid hardwood is susceptible to expansion and contraction with changes in humidity, which can lead to warping and cupping when installed over concrete.

Engineered wood flooring is a more suitable option for concrete slab installations. Engineered wood flooring consists of multiple layers of wood veneer bonded together, with a hardwood wear layer on top. This construction makes engineered wood flooring more dimensionally stable than solid hardwood, meaning it is less likely to expand and contract with changes in humidity. This stability is crucial when installing over concrete, where moisture levels can fluctuate.

There are several installation methods suitable for engineered wood flooring on concrete, including floating, gluing, and nailing (into wooden sleepers). The floating installation method involves placing the engineered wood flooring planks over a thin foam underlayment, allowing the floor to expand and contract as a single unit. This method is relatively easy to install and does not require fasteners. However, it may not be suitable for areas with heavy traffic or large temperature fluctuations.

The gluing method involves adhering the engineered wood flooring planks directly to the concrete slab using a specialized adhesive. This method provides a more secure and stable installation than the floating method, but it requires careful preparation of the concrete surface to ensure proper adhesion. The concrete surface must be clean, level, and free of dust, grease, and other contaminants.

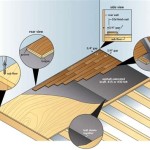

The nailing method involves installing wooden sleepers (typically 2x4s) onto the concrete slab and then nailing the engineered wood flooring planks to the sleepers. This method creates an air gap between the concrete slab and the wood flooring, which helps to prevent moisture problems. However, it requires more labor and materials than the floating or gluing methods and can raise the floor height significantly.

When selecting an installation method, it is important to consider the specific project requirements, including the moisture levels in the concrete, the type of wood flooring being used, and the level of traffic the floor will be subjected to.

Key Point 3: Preparing the Concrete Slab and Installing the Flooring

Proper preparation of the concrete slab is essential for a successful wood flooring installation. The concrete slab must be clean, level, and free of any cracks or imperfections. Any cracks should be repaired with a concrete patching compound. The surface should also be thoroughly cleaned to remove any dust, dirt, or debris. This can be accomplished by sweeping, vacuuming, and scrubbing the concrete surface.

Leveling the concrete slab is crucial for ensuring a flat and even wood floor. Any significant imperfections in the concrete surface should be addressed with a self-leveling compound. This compound is poured onto the concrete surface and spreads out to create a smooth, level surface. This process might require a professional to do.

After the concrete slab has been prepared and leveled, the wood flooring can be installed according to the chosen installation method. For a floating installation, a foam underlayment is first installed over the concrete slab. The wood flooring planks are then connected to each other, creating a floating floor that is not attached to the concrete. It is important to leave an expansion gap around the perimeter of the room to allow for expansion and contraction of the floor.

For a glue-down installation, a specialized adhesive is applied to the concrete slab. The wood flooring planks are then carefully placed onto the adhesive and pressed firmly into place. It is important to follow the adhesive manufacturer's instructions carefully, including the recommended spread rate and open time. Roll the floor with a heavy roller multiple times during the curing stage, usually within the first 24 hours.

For a nail-down installation, wooden sleepers are first installed onto the concrete slab using concrete fasteners. The wood flooring planks are then nailed to the sleepers. It is important to use the proper type of nails and nailing pattern to ensure a secure and stable installation. Again, follow all manufacturer instructions.

Once the wood flooring has been installed, trim pieces such as baseboards and transitions should be installed to complete the project. These trim pieces will cover the expansion gap around the perimeter of the room and provide a finished look. Allow the adhesive, nails, or other binding agent to cure completely before walking on the new floor.

Installing wood flooring over a cement slab requires careful planning, preparation, and execution. By following these guidelines and taking the necessary precautions, it is possible to create a beautiful and durable wood floor that will last for many years.

Remember to consult with flooring professionals and refer to manufacturer guidelines for specific product recommendations and installation instructions. This will ensure the successful and long-lasting installation of wood flooring over a concrete slab.

Installing Wood Flooring Over Concrete Diy

Hardwood Over Concrete Auten Wideplank Flooring

Q A Solid Wood Floors Over Concrete Slabs Jlc

Getting It Right Wood Flooring Over A Concrete Subfloor Page 2 Of 3 Construction Specifier

Installing Hardwood Floors On Concrete Subfloors

How Do I Install A Hardwood Floor On Concrete Slab The Carpet Guys

Installing Wood Subfloors Over Concrete Hardwood Floors

Installing Engineered Hardwood On Concrete Twenty Oak

How To Install A Wood Subfloor Over Concrete Rona

Installing A Hardwood Floor Over Concrete Slab American Information Center

Related Posts