How to Craft Exquisite Wood Flooring

Wood flooring adds warmth, character, and timeless elegance to any home. Creating your own wood flooring can be a rewarding and fulfilling project that allows you to customize the look and feel of your living space. Here's a comprehensive guide to help you navigate the intricate process of crafting wood flooring:

1. Choosing the Right Wood:

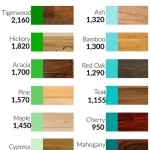

The choice of wood species will significantly impact the durability, aesthetics, and maintenance requirements of your flooring. Consider factors such as hardness, grain pattern, and moisture resistance. Popular flooring woods include oak, maple, cherry, walnut, and bamboo.

2. Milling the Lumber:

Once you have selected your wood, it needs to be milled into flooring planks. This involves cutting the lumber to the desired width, thickness, and tongue-and-groove profile. Ensure that the millwork is precise and consistent for a seamless installation.

3. Drying and Tempering:

Proper drying is crucial for preventing warping and shrinkage. Stack the planks in a controlled environment and allow them to dry slowly and evenly. Once dried, temper the wood to acclimatize it to the temperature and humidity levels of your home.

4. Finishing the Planks:

The finish you choose will protect and enhance the beauty of your flooring. Options include oil-based finishes, which penetrate the wood and provide a natural look, or water-based finishes, which create a more durable surface. Consider the desired sheen level and wear resistance.

5. Subfloor Preparation:

Before installing the wood flooring, ensure that the subfloor is level, dry, and free from imperfections. Install a vapor barrier to prevent moisture from damaging the wood. If necessary, level the subfloor using a self-leveling compound.

6. Installing the Flooring:

Wood flooring can be installed using various methods, including nailing, stapling, and floating. Floating floors are not attached directly to the subfloor but instead rest on an underlayment that provides cushioning and sound insulation.

7. Trimming and Edging:

After the flooring is installed, trim around the edges of the room to accommodate walls, baseboards, and other obstacles. Use a table saw or miter saw to cut the planks to the correct dimensions.

Make Your Own Plank Flooring Using 1 X 12 Lumber Hallstrom Home

Make Your Own Plank Flooring Using 1 X 12 Lumber Hallstrom Home

Inexpensive Wood Floor That Looks Like A Million Dollars

How To Make A Wooden Floor Mat Free Plans

How To Make 2x4 End Grain Floors

Make Your Own Plank Flooring Using 1 X 12 Lumber Hallstrom Home

Make Your Own Geometric Wood Flooring Manmadediy

How To Install An Inexpensive Wood Floor That Looks Like A Million Dollars Make Decoration Home Diy On Cut Out Keep

How To Make A Wooden Floor Mat Free Plans

How To Make Distressed Wood Floors The Craftsman Blog

Related Posts