How Thick Should Solid Wood Flooring Be? Understanding the Key Considerations

Solid wood flooring, prized for its beauty, durability, and longevity, remains a popular choice for homeowners seeking a timeless and elegant flooring solution. One crucial factor determining the performance and lifespan of solid wood flooring is its thickness. Selecting the appropriate thickness involves considering various factors, including subfloor condition, intended use, the chosen wood species, and budget. This article will provide a comprehensive overview of solid wood flooring thickness, exploring the key considerations that influence the optimal choice for different applications.

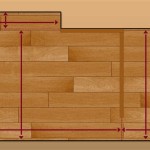

Solid wood flooring is typically available in thicknesses ranging from 5/16 inch to ¾ inch or even thicker for specialized applications. This measurement refers to the thickness of each individual plank, directly impacting the floor's stability, insulation, and potential for refinishing. While thinner options might seem appealing due to lower cost, they may not be suitable for all situations. Similarly, excessively thick planks can be overkill for certain applications, increasing material costs without providing significant tangible benefits.

The following sections will delve into the crucial aspects influencing solid wood flooring thickness selection, providing a detailed understanding of how to make an informed decision.

Subfloor Condition and Stability

The condition of the subfloor is a primary determinant of the required solid wood flooring thickness. A perfectly level and stable subfloor provides a solid foundation, allowing for a wider range of thickness options. Conversely, an uneven or unstable subfloor necessitates a thicker plank to minimize deflection and prevent issues like squeaking or movement. Deflection refers to the bending or displacement of the flooring material under load.

A subfloor with minor imperfections might be addressed through leveling compounds or shimming, potentially permitting the use of slightly thinner flooring. However, for subfloors with significant irregularities or structural concerns, opting for a thicker solid wood plank is almost always preferable. Thicker planks possess greater rigidity, bridging minor imperfections and distributing weight more evenly, resulting in a more stable and comfortable walking surface.

For installations over joists, particularly in older homes, the spacing and condition of the joists are paramount. Wider joist spacing demands thicker flooring to prevent bouncing or sagging between the supports. In such scenarios, a ¾ inch thick plank is generally recommended as the minimum, providing the necessary strength to withstand foot traffic and furniture weight. Conducting a thorough inspection of the subfloor and joist system is essential before deciding on the appropriate flooring thickness.

Furthermore, the type of subfloor also plays a role. Concrete subfloors, while generally stable, require proper moisture mitigation measures to prevent warping or cupping of the solid wood flooring. Using a thicker plank can help mitigate the effects of minor moisture fluctuations, but proper moisture barriers are still crucial. Plywood or OSB subfloors offer more flexibility but are also more susceptible to moisture damage, underscoring the importance of adequate ventilation and vapor barriers, irrespective of the flooring thickness.

Intended Use and Traffic Levels

The intended use of the room and the anticipated traffic levels significantly influence the optimal solid wood flooring thickness. High-traffic areas, such as hallways, living rooms, and kitchens, necessitate thicker, more durable flooring to withstand wear and tear. These areas are subjected to frequent foot traffic, furniture movement, and potential spills, making a robust flooring solution essential.

Thicker solid wood planks offer greater resistance to dents, scratches, and abrasions compared to thinner options. This translates to a longer lifespan and less frequent need for refinishing. For instance, in a busy family room, a ¾ inch thick plank is ideal, providing superior durability and the ability to withstand the rigors of daily life. In contrast, a less frequented bedroom might accommodate a slightly thinner plank, such as 5/8 inch, without compromising longevity.

Commercial applications, such as retail spaces or offices, often require even thicker flooring due to the exceptionally high traffic volume. In such settings, planks exceeding ¾ inch, or even specialized commercial-grade options, are typically recommended. These thicker planks are designed to withstand heavy machinery, rolling carts, and constant foot traffic, ensuring a durable and aesthetically pleasing floor for years to come.

Beyond traffic levels, consider the potential for impacts or heavy loads. If the flooring will be subjected to heavy furniture, exercise equipment, or other concentrated weight, a thicker plank is essential to prevent damage. While thinner options might suffice for areas with light furniture and minimal traffic, they are unlikely to withstand the stress of heavier loads, leading to premature wear and tear.

Wood Species and Stability Characteristics

The chosen wood species is another critical factor influencing the necessary solid wood flooring thickness. Different wood species exhibit varying degrees of hardness, density, and dimensional stability. Harder, denser woods like oak, maple, and hickory are naturally more resistant to dents and scratches, potentially allowing for slightly thinner planks compared to softer woods.

Softer wood species, such as pine or fir, are more susceptible to damage and require greater thickness to compensate for their lower density. Using a thicker plank of a softer wood provides added protection against dents and wear, ensuring a longer lifespan. For instance, if pine is chosen for its aesthetic appeal in a high-traffic area, opting for a ¾ inch thick plank is crucial to mitigate its inherent softness.

Dimensional stability refers to a wood's ability to resist expansion and contraction in response to changes in humidity. Wood naturally expands when exposed to moisture and contracts when dry. Species with higher dimensional stability, such as some engineered hardwood varieties, are less prone to warping or cupping, potentially allowing for thinner installations. However, solid wood flooring generally exhibits greater movement than engineered options, making thickness a more significant consideration.

Consider the grain pattern of the wood as well. More intricate or figured grain patterns can sometimes weaken the wood structure, making a slightly thicker plank advisable. Highly figured grain patterns, while visually appealing, can create areas of stress within the wood, potentially leading to splits or cracks, especially in thinner planks. Therefore, when selecting a wood species with a complex grain pattern, err on the side of caution and opt for a slightly thicker option.

The wood's origin and drying process also impact its stability. Properly kiln-dried wood is less prone to warping or cupping than wood that has not been adequately dried. Sourcing wood from reputable suppliers who adhere to strict drying standards is crucial, regardless of the chosen thickness. This ensures that the wood is stable and less likely to experience excessive movement after installation.

In addition to these considerations, the cost of different wood species and thicknesses must also be factored into the decision-making process. Harder, denser woods are typically more expensive than softer woods, and thicker planks generally cost more than thinner planks. Balancing the desired aesthetic, durability, and budget is essential when selecting solid wood flooring.

Solid Wood Flooring Thickness Guide And Beyond Blog

Solid Wood Flooring Vs Engineered

How Thick Should Engineered Wood Flooring Be And Beyond Blog

Wood Flooring Blog How Thick Should My Oak Be Peak

Our Thick 6mm Wear Layer Engineered Wood Flooring Is Better

Wear Layers On Engineered Flooring

The Ideal Hardwood Floor Thickness For Homeowners

What To Consider When Choosing Your Wood Flooring Thickness Hardwoods4less Com

The Optimal Thickness For Engineered Wood Flooring And Beyond Blog

3 4 Inch Thick Engineered Baltic Birch Ply 5 8 Mm Wear Layer

Related Posts