French White Oak Engineered Flooring: A Comprehensive Guide

French White Oak engineered flooring has emerged as a popular choice for both residential and commercial spaces. Its combination of aesthetic appeal, durability, and stability offers a compelling alternative to solid hardwood, while its lower cost compared to other exotic wood species makes it an accessible option for a wide range of budgets. This article aims to provide a comprehensive overview of French White Oak engineered flooring, covering its characteristics, benefits, installation considerations, maintenance, and cost factors.

The "French White Oak" designation refers to oak trees sourced from forests in France. While White Oak is also found in North America, the European variety, particularly that grown in France, is often prized for its tight grain structure and consistent color. These characteristics contribute to its desirable appearance when used in flooring.

The "engineered" aspect of the flooring describes its construction. Unlike solid hardwood, engineered flooring consists of multiple layers of wood bonded together. French White Oak engineered flooring typically features a top layer, or veneer, of genuine French White Oak. This veneer is adhered to a core made of plywood, High-Density Fiberboard (HDF), or softwood. The multi-layered construction provides enhanced stability and resistance to warping and moisture damage compared to solid hardwood.

Understanding the Structure of Engineered Flooring

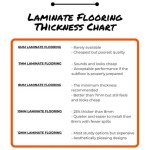

The construction of engineered flooring is crucial to its performance and longevity. The top layer, or wear layer, is the most important factor in determining the floor's durability. A thicker wear layer allows for more refinishing over the floor's lifetime. The common thicknesses range from 2mm to 6mm. A thicker wear layer is usually more expensive, but it will significantly extend the life of the flooring.

The core layer provides the bulk of the flooring's thickness and contributes to its stability. Plywood cores are known for their excellent moisture resistance and dimensional stability, making them a good choice for areas with moderate humidity fluctuations. HDF cores offer high density and impact resistance, but they may be more susceptible to moisture damage than plywood. Softwood cores are often used in less expensive engineered flooring options.

The bottom layer, or backer, provides a stable foundation and often features a moisture barrier. This layer helps to prevent moisture from rising up through the subfloor and damaging the flooring. Many engineered floorings come with attached underlayment as well, which is an added layer of padding to help with sound absorption and make the flooring more comfortable underfoot.

Advantages of French White Oak Engineered Flooring

French White Oak engineered flooring offers a number of advantages over solid hardwood and other flooring options. These advantages contribute to its increasing popularity among homeowners and builders. The benefits encompass aesthetics, performance, and cost-effectiveness.

One of the primary advantages is its stability. The multi-layered construction minimizes expansion and contraction due to changes in humidity and temperature. This makes it suitable for installation in areas where solid hardwood might not be appropriate, such as basements or over concrete slabs. The dimensional stability also reduces the risk of gapping and cupping, maintaining the floor's aesthetic appeal over time.

Another key benefit is its versatility. Engineered flooring can be installed using various methods, including nailing, stapling, gluing, or floating. This flexibility allows for installation over different subfloors and in different environments. Floating installations, in particular, are often favored for their ease and speed.

Furthermore, French White Oak engineered flooring offers a wide range of design options. The top veneer can be stained, finished, and textured to achieve a variety of looks, from traditional to contemporary. Different plank widths, lengths, and surface treatments allow for customization to match any architectural style. Many options exist from smooth surfaces to hand-scraped textures.

Compared to solid French White Oak flooring, the engineered version is often more cost-effective. This is due to the more efficient use of the valuable French White Oak wood. The core layers are typically made of less expensive materials, reducing the overall cost without sacrificing the aesthetic appeal of the top veneer.

Finally, many engineered flooring products are manufactured with sustainable practices. Responsible forestry management ensures that the wood is harvested in an environmentally friendly manner. Many manufacturers also use low-VOC (volatile organic compound) adhesives and finishes, contributing to better indoor air quality.

Installation and Maintenance Considerations

Proper installation and maintenance are essential for maximizing the lifespan and appearance of French White Oak engineered flooring. Incorrect installation can lead to problems such as buckling, gapping, and squeaking. Regular maintenance, including cleaning and refinishing (if the wear layer is thick enough), will help to keep the floor looking its best for years to come.

Before installation, it's crucial to acclimate the flooring to the environment in which it will be installed. This involves allowing the flooring to sit in the room for several days to adjust to the temperature and humidity levels. Proper acclimation minimizes expansion and contraction after installation.

The subfloor must be clean, level, and dry before installation. Any imperfections in the subfloor can telegraph through the flooring, creating an uneven surface. Moisture testing is also essential to ensure that the subfloor is within acceptable moisture levels. Failure to address moisture issues can lead to significant problems down the road.

During installation, it's important to follow the manufacturer's instructions carefully. Different installation methods require different techniques and tools. For example, floating installations require the use of an underlayment to provide cushioning and sound insulation. Glued-down installations require a specific type of adhesive that is compatible with the flooring and the subfloor.

Regular cleaning is essential for maintaining the appearance of French White Oak engineered flooring. Sweep or vacuum the floor regularly to remove dirt and debris. Use a damp mop with a pH-neutral cleaner specifically designed for hardwood floors. Avoid using excessive water, as it can damage the flooring over time. Never use abrasive cleaners or scouring pads, as they can scratch the surface.

Depending on the thickness of the wear layer, French White Oak engineered flooring can be refinished multiple times. Refinishing involves sanding down the old finish and applying a new stain and topcoat. This can restore the floor to its original beauty and extend its lifespan. Consult with a professional flooring contractor to determine if refinishing is appropriate for your flooring.

For areas with heavy foot traffic, consider using area rugs to protect the flooring from excessive wear. Also, use furniture pads under the legs of furniture to prevent scratches and dents. Promptly clean up any spills to prevent staining and water damage.

Be aware that extended exposure to direct sunlight can, over time, cause the flooring to fade. To mitigate this have blinds and curtains available, or consider UV-blocking window film.

Cost Considerations

The cost of French White Oak engineered flooring can vary depending on a number of factors, including the thickness of the wear layer, the type of core material, the finish, the plank width, and the installation method. It's important to consider all of these factors when budgeting for a flooring project.

Generally, engineered flooring is less expensive than solid hardwood flooring. However, the price can still range from moderate to high, depending on the quality of the materials and the complexity of the installation. The thickness of the wear layer is a significant cost factor. A thicker wear layer will typically cost more, but it will also provide greater durability and allow for more refinishing over the floor's lifetime.

The type of core material also affects the cost. Plywood cores are generally more expensive than HDF or softwood cores. However, plywood cores offer better moisture resistance and dimensional stability, making them a worthwhile investment in areas with high humidity or potential for moisture exposure. The species of the core can also influence the price, with Baltic Birch plywood often commanding a premium.

Installation costs can vary depending on the complexity of the project and the chosen installation method. Floating installations are typically less expensive than glued-down or nailed-down installations. However, floating installations may not be suitable for all subfloors or environments. Professional installation will add to the overall cost, but it can ensure that the flooring is installed correctly and will perform as expected.

Additional costs to consider include the cost of removing existing flooring, preparing the subfloor, purchasing underlayment, and disposing of waste materials. It's important to obtain multiple quotes from different flooring contractors to ensure that you are getting a fair price. Be sure to ask about the contractor's experience, qualifications, and insurance coverage. It's also a good idea to check online reviews and ask for references.

The Forest Modern Our Aged French Oak Hardwood Floors House Of Silver Lining

10 1 4 X 3 European French Oak Unfinished Square Edge W 6mm Wear Layer Reserve Hardwood Flooring

French Oak Artisano Bridgeport Engineered Brushed Character

7 Ply Engineered Wood 9 Wide 75 Rl Long Plank French White Oak Floret

Palladio Hardwood French White Oak Driftwood 58752t

Engineered French Oak Flooring 8 5 In Wide Plank Clt Wood

Everything You Need To Know About White Oak Flooring Twenty

7 1 2 X 5 8 European French Oak Unfinished Square Edge Hardwood Flooring

7 1 2 X European French Oak Riviera Antique White Prefinished Engineered Wood Flooring Floors Wide Plank

Antique And Aged French Oak Flooring Vintage Historic Decorative Materials A Division Of Pavé Tile Wood Stone Inc

Related Posts