Flooring Options Over Concrete Slab: A Comprehensive Guide

Concrete slabs provide a durable and common subfloor in residential and commercial buildings. However, concrete itself is rarely the desired finished flooring material. It's cold, hard, and can be susceptible to moisture issues. Therefore, selecting the right flooring option to install over a concrete slab is crucial for comfort, aesthetics, and long-term performance. This article will explore various flooring options, their advantages, disadvantages, and key considerations for installation over a concrete slab.

The choice of flooring over concrete depends on several factors, including budget, desired aesthetic, level of traffic, moisture conditions, and required durability. Each flooring material has its own unique properties and installation requirements, which must be carefully evaluated to ensure a successful and long-lasting result. Failure to properly prepare the concrete slab or choose an incompatible flooring material can lead to problems such as adhesive failure, warping, mold growth, and ultimately, the need for costly repairs or replacement.

Key Point 1: Understanding Concrete Slab Considerations

Before installing any flooring over a concrete slab, it's essential to thoroughly assess the slab's condition. Factors like flatness, moisture content, and the presence of cracks are critical to determine the appropriate preparation steps. A new concrete slab requires a curing period, typically 30-60 days, before flooring installation to allow excess moisture to dissipate. Even existing slabs can retain moisture, which can cause problems with adhesives and flooring materials if not addressed.

Moisture Testing: Moisture testing is paramount. A simple plastic sheet test can provide a preliminary indication of moisture levels. This involves taping a square of plastic (approximately 18" x 18") onto the concrete slab and leaving it for 24-72 hours. If condensation forms under the plastic, it suggests the slab has elevated moisture levels. More accurate methods involve using a calcium chloride test (anhydrous calcium chloride placed under a sealed dome) or an electronic moisture meter. These tests quantify the moisture vapor emission rate (MVER), which indicates the amount of moisture passing through the slab over a given period.

Slab Flatness: The flatness of the concrete slab is equally important. Uneven surfaces can cause flooring materials to flex, crack, or become uneven over time. A straightedge or level is used to check for high and low spots. Self-leveling compounds can be applied to correct minor imperfections. For more significant undulations, grinding or patching may be necessary to achieve a sufficiently flat surface for the chosen flooring.

Crack Assessment: Cracks in the concrete slab should be evaluated for their severity and stability. Hairline cracks are generally not a concern, but wider cracks or those that appear to be actively moving require professional attention. Filling cracks with a suitable patching compound or epoxy can prevent moisture from penetrating the slab and compromising the flooring installation. In some cases, structural cracks may necessitate structural repair before any flooring is installed.

Cleaning and Preparation: Before applying any adhesive or underlayment, the concrete slab must be thoroughly cleaned to remove dust, debris, and any existing coatings or sealers. Grinding or shot blasting may be necessary to provide a clean, porous surface for optimal adhesion. A primer may also be required to improve the bond between the concrete and the flooring material.

Key Point 2: Exploring Common Flooring Options

Numerous flooring options are suitable for installation over concrete slabs. Each material offers unique advantages and disadvantages in terms of aesthetics, durability, cost, and installation requirements.

Epoxy Flooring: Epoxy flooring is a durable and seamless option, often used in garages, basements, and commercial spaces. It is resistant to chemicals, stains, and impact. Epoxy coatings can be customized with various colors, patterns, and textures. However, epoxy requires professional installation and can be more expensive than other options.

Polished Concrete: Polished concrete involves grinding and polishing the existing concrete slab to achieve a smooth, glossy finish. It is a durable and low-maintenance option that can be stained or dyed to create a variety of colors and patterns. Polished concrete is a good choice for modern or industrial-style spaces but it can be cold underfoot.

Tile Flooring (Ceramic, Porcelain, Stone): Tile is a popular choice for concrete slabs due to its durability, water resistance, and variety of styles. Ceramic, porcelain, and natural stone tiles are all suitable options. Tile requires a strong and stable subfloor. A cement backer board is often installed over the concrete slab to provide a level and waterproof surface for tile installation. Grouting and sealing are essential to protect the tile and prevent water damage.

Luxury Vinyl Tile (LVT) and Luxury Vinyl Plank (LVP): LVT and LVP are resilient flooring options that mimic the look of wood, stone, or tile. They are durable, water-resistant, and relatively easy to install. LVT and LVP come in various thicknesses and installation methods, including glue-down and click-lock systems. A smooth and level subfloor is crucial for a successful LVT or LVP installation. Minor imperfections in the concrete slab can telegraph through thinner products.

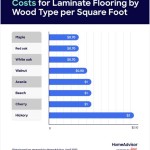

Laminate Flooring: Laminate flooring is a cost-effective option that provides the look of hardwood at a lower price. Laminate is relatively easy to install with a click-lock system. However, laminate is not as water-resistant as other options and should not be used in areas prone to moisture. An underlayment is required to provide cushioning, sound insulation, and moisture protection.

Hardwood Flooring: Solid hardwood flooring can be installed over a concrete slab, but it requires careful preparation and a moisture barrier. Engineered hardwood is a more stable option for concrete slabs, as it is less susceptible to warping and expansion from moisture. Hardwood flooring typically requires a plywood subfloor to be installed over the concrete before the hardwood is installed. This creates an air gap that helps prevent moisture damage.

Carpet: Carpet is a soft and comfortable flooring option that is suitable for bedrooms and living areas. Carpet can be installed directly over a concrete slab with a suitable padding. The padding provides cushioning, insulation, and moisture protection. It is important to choose a carpet that is resistant to mold and mildew, especially in areas with high humidity. Staining and cleaning need to be considered based on foot traffic

Key Point 3: Addressing Moisture Mitigation

Moisture mitigation is a critical aspect of flooring installation over concrete slabs. Concrete is porous and can wick moisture from the ground, which can lead to problems such as mold growth, adhesive failure, and flooring damage. Implementing effective moisture mitigation strategies is essential for ensuring the longevity and performance of the flooring.

Moisture Barriers: Moisture barriers are membranes or coatings that are applied to the concrete slab to prevent moisture from migrating upwards. These barriers can be made of polyethylene film, epoxy coatings, or cementitious coatings. The choice of moisture barrier depends on the moisture levels in the slab and the type of flooring being installed. It is important to choose a moisture barrier that is compatible with the flooring adhesive.

Underlayments: Underlayments provide a layer of cushioning and insulation between the concrete slab and the flooring material. Some underlayments also include a built-in moisture barrier. Underlayments can help to reduce noise transmission and improve the comfort of the flooring. Ensure the underlayment chosen is recommended for the specific flooring.

Vapor Retarders: Vapor retarders are typically installed under the concrete slab during construction to prevent moisture from entering the slab from the ground. However, if a vapor retarder is not present or is damaged, supplemental moisture mitigation strategies may be necessary.

Ventilation: Adequate ventilation can help to reduce moisture levels in the concrete slab. Ensuring proper airflow in the room can help to prevent condensation and mold growth. Dehumidifiers can be used to remove excess moisture from the air.

Professional Consultation: Consulting with a flooring professional or moisture mitigation specialist is recommended to assess the moisture levels in the concrete slab and recommend the appropriate mitigation strategies. A professional can also perform moisture testing and provide guidance on the selection of suitable flooring materials and adhesives.

By carefully assessing the concrete slab, selecting the appropriate flooring material, and implementing effective moisture mitigation strategies, it is possible to achieve a successful and long-lasting flooring installation over a concrete slab.

What Are The Best Flooring Options For A Concrete Substrate And Design

Installing Wood Flooring Over Concrete Diy

Ultimate Guide To Floor Covering Over Concrete Surfaces Carpetace

Best Basement Flooring Options Cork Floating Floors Icork Floor

How To Choose The Right Floor For Your Basement Gc Flooring Pros

Polished Concrete Flooring Options For Your Basement Duraamen

What Are Some Best Value Industrial Flooring Options

2024 Buyer S Guide Best Basement Flooring Over Concrete

6 Inspiring Ideas For Basement Flooring In Portland

Best Flooring For Concrete Slabs 50floor

Related Posts