Flooring Choices For Concrete Slab

Concrete slabs are a common foundation for residential and commercial buildings, offering a durable and versatile base for a variety of flooring materials. Selecting the appropriate flooring for a concrete slab requires careful consideration of factors such as aesthetics, durability, comfort, moisture resistance, and budget. This article explores various flooring options suitable for concrete slabs, outlining their advantages, disadvantages, and key considerations for installation.

Moisture Considerations

One of the most critical factors to address when selecting flooring for a concrete slab is moisture. Concrete is porous and can absorb moisture from the ground or the surrounding environment. Excess moisture can lead to the growth of mold and mildew, damage flooring materials, and compromise indoor air quality. Before installing any flooring, it is crucial to test the concrete slab for moisture levels. Common methods include the calcium chloride test, which measures the rate of moisture vapor emission, and the relative humidity probe test, which measures the humidity within the slab. A vapor barrier or moisture mitigation system may be necessary if moisture levels are high. This barrier prevents moisture from migrating through the concrete and damaging the flooring above.

Certain flooring materials are more resistant to moisture than others. For example, ceramic and porcelain tile are naturally waterproof and ideal for areas prone to moisture, such as bathrooms and kitchens. Engineered hardwood is more dimensionally stable and less susceptible to warping than solid hardwood when exposed to moisture. Vinyl flooring, particularly sheet vinyl and luxury vinyl tile (LVT), offers excellent moisture resistance and is well-suited for below-grade installations or areas with high humidity.

Proper surface preparation is also essential for preventing moisture-related issues. The concrete slab should be clean, level, and free from any cracks or imperfections. Cracks should be repaired using a concrete patching compound, and the surface should be leveled using a self-leveling underlayment if necessary. A clean, smooth surface ensures proper adhesion of the flooring material and minimizes the risk of moisture penetrating the flooring system.

Furthermore, consider the climate and the building's location. Areas with high rainfall or proximity to bodies of water are more likely to experience moisture issues. Selecting flooring materials and installation methods that are appropriate for the local climate can help to protect the flooring and prevent moisture-related problems.

Popular Flooring Options

Several flooring options are frequently chosen for concrete slabs, each offering unique benefits and drawbacks. A comprehensive understanding of these options is crucial for making an informed decision that aligns with specific needs and preferences.

Ceramic and Porcelain Tile: Ceramic and porcelain tile are highly durable, water-resistant, and easy to maintain. They are available in a wide range of colors, sizes, and styles, making them a versatile choice for various design aesthetics. Tile is ideal for high-traffic areas, bathrooms, and kitchens due to its resistance to scratches, stains, and moisture. However, tile can be cold and hard underfoot, necessitating rugs or radiant floor heating for added comfort.

Installation of tile requires a cement-based mortar and grout. Proper surface preparation is essential to ensure a level and stable base for the tile. The grout lines should be sealed to prevent moisture penetration and staining. While tile is a durable and long-lasting option, it can be more expensive to install than some other flooring materials.

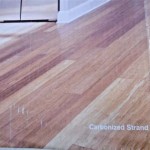

Engineered Hardwood: Engineered hardwood consists of a thin layer of real wood veneer bonded to multiple layers of plywood or high-density fiberboard (HDF). This construction makes it more dimensionally stable than solid hardwood, reducing the risk of warping or cupping in response to moisture fluctuations. Engineered hardwood offers the aesthetic appeal of solid hardwood with improved durability and moisture resistance.

Engineered hardwood can be installed using various methods, including floating, gluing, or nailing. Floating installations are popular as they do not require direct attachment to the concrete slab, allowing for some movement and expansion. A vapor barrier is typically installed beneath the engineered hardwood to protect it from moisture. While engineered hardwood is more resistant to moisture than solid hardwood, it is still susceptible to damage from excessive moisture exposure.

Luxury Vinyl Tile (LVT) and Luxury Vinyl Plank (LVP): LVT and LVP are manufactured vinyl products designed to mimic the look of natural materials such as wood, stone, and tile. They offer excellent durability, water resistance, and ease of maintenance. LVT and LVP are available in a wide range of colors, patterns, and textures, providing numerous design options. These options are typically more affordable than natural materials and are relatively easy to install.

LVT and LVP can be installed using various methods, including click-lock, glue-down, or loose-lay. Click-lock installations are popular for their ease of installation and minimal preparation requirements. Glue-down installations offer greater stability and are suitable for high-traffic areas. A smooth and level subfloor is essential for successful LVT and LVP installation. While LVT and LVP are water-resistant, they are not entirely waterproof, and prolonged exposure to standing water can still cause damage.

Laminate Flooring: Laminate flooring consists of a high-density fiberboard (HDF) core topped with a decorative layer and a clear protective wear layer. Laminate offers a realistic imitation of wood, stone, and tile at a more affordable price point. It is durable, scratch-resistant, and easy to clean. However, laminate is not as water-resistant as vinyl flooring and can be damaged by prolonged exposure to moisture. Proper maintenance, including prompt cleanup of spills, is essential to prevent water damage.

Laminate flooring is typically installed using a click-lock system, which allows for easy floating installation over a concrete slab. A vapor barrier is required to protect the laminate from moisture. While laminate is a cost-effective and aesthetically pleasing option, it is not suitable for areas with high moisture levels, such as bathrooms and laundry rooms.

Polished Concrete: Polished concrete is a flooring option that involves grinding and polishing the existing concrete slab to create a smooth, durable, and aesthetically pleasing surface. Polished concrete offers a modern and industrial look and is highly resistant to wear and tear. It is also relatively easy to maintain and can be customized with various colors, stains, and finishes. However, polished concrete can be cold and hard underfoot and may require sealing to prevent staining. Polished concrete represents a relatively sustainable option, as it reuses existing material and reduces the need for additional materials and installations.

The polishing process involves several stages of grinding with progressively finer diamond abrasives. The final finish can range from a matte to a high-gloss sheen. Polished concrete is a durable and long-lasting flooring option that is well-suited for both residential and commercial applications. It is particularly popular in modern and minimalist designs. It is also a good choice for those concerned with volatile organic compounds (VOCs) because it generally does not require chemicals that often off-gas.

Carpet: Carpet provides warmth, comfort, and sound absorption, making it a popular choice for bedrooms and living rooms. Carpet is available in a wide range of colors, textures, and styles, offering numerous design options. However, carpet is susceptible to stains, moisture damage, and allergens. Proper maintenance, including regular vacuuming and professional cleaning, is essential to keep carpet clean and healthy. Carpet tiles represent an alternative to broadloom carpeting that is easier to maintain. Damaged tiles can be easily replaced without disrupting the entire floor.

Carpet can be installed directly on the concrete slab or over a carpet pad. A carpet pad provides added cushioning and insulation, enhancing comfort and reducing noise. It also helps to protect the carpet from wear and tear. A vapor barrier is recommended to protect the carpet from moisture. Carpet is not recommended for areas with high moisture levels, such as bathrooms and kitchens.

Installation Considerations

Proper installation is crucial for ensuring the longevity and performance of any flooring material installed over a concrete slab. Several factors need to be considered during the installation process to prevent problems such as moisture damage, unevenness, and premature wear.

Surface Preparation: As previously mentioned, proper surface preparation is essential for successful flooring installation. The concrete slab should be clean, level, and free from any cracks or imperfections. Any existing coatings, adhesives, or contaminants should be removed. Cracks should be repaired using a concrete patching compound, and the surface should be leveled using a self-leveling underlayment if necessary. A clean and level surface ensures proper adhesion of the flooring material and minimizes the risk of installation-related problems.

Acclimation: Many flooring materials, such as engineered hardwood, laminate, and vinyl, require acclimation before installation. Acclimation involves allowing the flooring material to adjust to the temperature and humidity of the installation environment. This process helps to prevent expansion or contraction after installation, which can lead to warping or gapping. The manufacturer's instructions should be followed carefully regarding acclimation duration and conditions.

Adhesives and Fasteners: The appropriate adhesives and fasteners should be selected based on the type of flooring material and the installation method. Cement-based mortars are typically used for tile installations, while specialized adhesives are used for vinyl and laminate flooring. The manufacturer's recommendations should be followed regarding the selection and application of adhesives and fasteners. Incorrect adhesives or fasteners can lead to poor adhesion and premature failure of the flooring system.

Expansion Gaps: Expansion gaps should be left around the perimeter of the room and around any vertical obstructions, such as pipes or columns. These gaps allow for expansion and contraction of the flooring material in response to temperature and humidity changes. Expansion gaps are typically covered by baseboards or trim. Failure to provide adequate expansion gaps can lead to buckling or cracking of the flooring.

Professional Installation: While some flooring materials can be installed by experienced DIYers, professional installation is often recommended, especially for complex installations or when dealing with specific challenges such as moisture issues or uneven subfloors. Professional installers have the knowledge, skills, and equipment to ensure a proper and long-lasting installation. Hiring a qualified installer can provide peace of mind and prevent costly mistakes.

Pros And Cons Of Polished Concrete Floors Craftsman

47 Inspiring Concrete Floor Ideas To Transform Your Home Kitchen Tile House Flooring

The Pros And Cons Of Concrete Flooring

An In Depth Look At 30 Concrete Floor Designs Flooring Solutions

Best Flooring For Concrete Slabs 50floor

31 Concrete Flooring Ideas With Pros And Cons Digsdigs

9 Types Of Concrete Floor Finishes For Your Home

What Are The Best Flooring Options For A Concrete Substrate And Design

An In Depth Look At 30 Concrete Floor Designs Flooring Solutions

An In Depth Guide To Polished Concrete Floors

Related Posts