Expresso Press And Go Vinyl Plank Flooring Installation: A Comprehensive Guide

Expresso Press And Go vinyl plank flooring offers a convenient and aesthetically pleasing option for homeowners seeking an easy-to-install and durable flooring solution. This type of flooring is characterized by its click-lock system, which allows for a floating installation, minimizing the need for adhesives and professional installers. This article provides a comprehensive guide to installing Expresso Press And Go vinyl plank flooring, outlining the necessary tools, preparatory steps, and installation techniques to achieve a professional-looking result.

The appeal of Expresso Press And Go vinyl plank flooring lies in its ease of installation, durability, and aesthetic versatility. It is often designed to mimic the look of natural wood or stone, providing a cost-effective alternative to more expensive materials. Furthermore, vinyl plank flooring generally offers water resistance, making it suitable for installation in areas prone to moisture, such as kitchens, bathrooms, and basements. However, it is important to always check the manufacturer's specifications regarding the specific water resistance rating of the chosen product.

Before embarking on the installation process, a thorough understanding of the requirements and procedures is crucial for a successful outcome. This article will cover the essential aspects, from preparing the subfloor to the final finishing touches, providing a step-by-step guide to ensure a smooth and efficient installation.

Key Point One: Preparing the Subfloor for Expresso Press And Go Installation

The subfloor serves as the foundation for the vinyl plank flooring, and its condition directly impacts the final result. A properly prepared subfloor ensures a level, stable, and clean surface for the planks to be installed upon. Improper subfloor preparation can lead to uneven flooring, premature wear, and potential damage to the planks themselves. Therefore, meticulous attention must be paid to preparing the subfloor before proceeding with the installation.

The first step in preparing the subfloor is to assess its condition. This involves checking for any signs of damage, such as cracks, holes, or unevenness. Any significant imperfections must be addressed before proceeding. Small cracks can often be filled with a concrete patching compound, while larger holes may require more extensive repairs.

Next, the subfloor must be leveled. Using a level and straight edge, identify any areas that are significantly higher or lower than the surrounding surface. High spots can be ground down using a concrete grinder, while low spots can be filled with a self-leveling compound. It is essential to follow the manufacturer’s instructions for the self-leveling compound to ensure proper application and curing. Remember that the goal is to achieve a flat and level surface across the entire area where the flooring will be installed. An uneven subfloor translates to uneven flooring and potential issues with the locking mechanism of the planks.

Cleanliness is also paramount. The subfloor must be thoroughly cleaned to remove any dirt, dust, debris, or adhesives. A vacuum cleaner is effective for removing loose particles, while stubborn residue may require scraping or the use of a specialized cleaning solution. Ensure the subfloor is completely dry before proceeding with the next step.

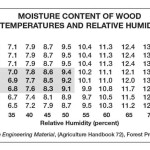

Finally, consider the existing subfloor material. Common subfloor materials include concrete, plywood, and OSB (Oriented Strand Board). Each material may require specific preparation techniques. For example, plywood or OSB subfloors may need to be reinforced with additional screws to prevent movement or squeaking. It is also important to ensure that the subfloor is adequately protected from moisture, especially in areas prone to humidity. A moisture barrier might be necessary depending on the manufacturer's recommendations and the conditions of the room.

Key Point Two: Essential Tools and Materials for Expresso Press And Go Installation

Having the right tools and materials readily available is crucial for a smooth and efficient Expresso Press And Go vinyl plank flooring installation. Using the appropriate tools not only simplifies the process but also ensures a higher quality result. This section outlines the essential tools and materials needed for the project.

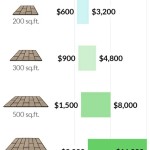

Firstly, a measuring tape is indispensable for accurately measuring the room and calculating the amount of flooring required. It is always advisable to purchase slightly more flooring than calculated to account for cuts and waste. A utility knife with sharp blades is essential for scoring and cutting the vinyl planks. A scoring tool designed specifically for vinyl flooring can also be used, providing a cleaner and more precise cut.

A rubber mallet is needed for gently tapping the planks together, ensuring a tight and secure connection. Avoid using a metal hammer, as it can damage the planks. A tapping block, often made of plastic or rubber, protects the edges of the planks while being tapped with the mallet.

Spacers are used to maintain a consistent expansion gap around the perimeter of the room. This gap allows for the natural expansion and contraction of the flooring due to temperature and humidity changes, preventing buckling or warping. A pencil or marker is needed for marking cutting lines and identifying planks during installation.

A level and straight edge are essential for ensuring the subfloor is level and for guiding cuts. A vacuum cleaner is necessary for cleaning the subfloor and removing debris during installation. Safety glasses and gloves are recommended to protect your eyes and hands during the cutting and installation process.

Depending on the existing subfloor and the manufacturer's recommendations, a moisture barrier may be required. This barrier prevents moisture from seeping up from the subfloor and damaging the vinyl planks. Finally, transition strips are used to create a smooth and aesthetically pleasing transition between the vinyl plank flooring and other types of flooring, such as carpet or tile.

Key Point Three: Step-by-Step Installation of Expresso Press And Go Vinyl Plank Flooring

The installation of Expresso Press And Go vinyl plank flooring involves a systematic approach to ensure a secure and visually appealing outcome. This section provides a step-by-step guide to installing the flooring, from the initial layout to the final finishing touches.

Begin by acclimating the vinyl planks to the room for at least 48 hours before installation. This allows the planks to adjust to the temperature and humidity of the room, minimizing expansion and contraction issues after installation. Store the planks flat in the room where they will be installed.

Determine the direction of the planks. Consider the room's layout and the direction of the natural light. Generally, planks are installed parallel to the longest wall or the direction of the primary light source. Snap a chalk line to guide the first row of planks, ensuring it is straight and parallel to the wall.

Start the first row of planks along the chalk line, leaving the recommended expansion gap between the planks and the wall. Use spacers to maintain a consistent gap. Connect the first few planks by aligning the locking mechanisms and gently tapping them together with a rubber mallet and tapping block. Ensure the planks are securely locked together and flush with each other.

Continue installing subsequent rows of planks, staggering the end joints for a more visually appealing and structurally sound floor. Staggering the joints also helps to distribute the weight evenly and prevent long, continuous weak points in the flooring. When installing each plank, ensure the locking mechanisms are properly aligned and engage completely. Use the rubber mallet and tapping block to gently tap the planks together until they are securely locked.

When reaching walls or other obstructions, measure and cut the planks to fit. Use a utility knife to score the plank along the cutting line, then snap it along the score. For more complex cuts, a jigsaw may be required. Ensure the cut edges are clean and smooth.

For the final row of planks, it may be necessary to rip the planks to width. Measure the remaining space and cut the planks accordingly, remembering to leave the expansion gap. Use a pull bar to engage the locking mechanisms on the final row of planks, ensuring they are securely locked to the adjacent row.

Finally, install transition strips at doorways and where the vinyl plank flooring meets other types of flooring. The transition strips provide a smooth and aesthetically pleasing transition between the different flooring materials. Remove the spacers around the perimeter of the room and install baseboards to cover the expansion gap. Ensure the baseboards are securely attached to the wall and not to the flooring itself, allowing the flooring to expand and contract freely.

After the installation is complete, inspect the flooring for any gaps or imperfections. Clean the floor with a damp cloth to remove any dust or debris. Avoid using harsh chemicals or abrasive cleaners, as they can damage the surface of the vinyl plank flooring. Regular cleaning and maintenance will help to prolong the life of the flooring and maintain its appearance.

Expresso Press Go Luxury Vinyl Plank Flooring

Expresso Press Go Luxury Vinyl Plank Flooring

Planches Press Go Shnier Expresso

Expresso Press Go Luxury Vinyl Plank Flooring

Quality Craft 24 Sq Ft 6 X 36 10mm Snowcap Press Go Expresso Vinyl Plank Flooring Home Hardware

Quality Craft 24 Sq Ft 6 X 36 10mm Edelweiss Press Go Expresso Vinyl Plank Flooring Home Hardware

Quality Craft 24 Sq Ft 6 X 36 10mm Alpine Press Go Expresso Vinyl Plank Flooring Home Hardware

Quality Craft 24 Sq Ft 6 X 36 10mm Rhone Press Go Expresso Vinyl Plank Flooring Home Hardware

24 Sq Ft 6 X 36 10mm Mont Blanc Press And Go Expresso Vinyl Plank Flooring

Quality Craft 24 Sq Ft 6 X 36 10mm Mont Blanc Press Go Expresso Vinyl Plank Flooring Home Hardware

Related Posts