Can You Whitewash Engineered Wood Flooring? A Comprehensive Guide

Whitewashing engineered wood flooring can be a desirable method to achieve a light, airy aesthetic in a home. The question, however, is whether it's achievable and what considerations need to be taken into account. This article will delve into the feasibility, the process, potential challenges, and essential precautions concerning whitewashing engineered wood floors.Engineered wood flooring is constructed with a thin veneer of hardwood bonded to a core of multiple layers of plywood or high-density fiberboard (HDF). This construction method makes it more stable than solid hardwood, less susceptible to warping, and generally more adaptable to different environments. However, this layered structure also impacts the potential for refinishing, including whitewashing. The thickness of the top veneer will determine the success and longevity of the whitewashed finish.

Whitewashing, in essence, is a technique that involves applying a diluted paint or specifically formulated whitewash stain to wood. The diluted application allows some of the wood grain to show through, creating a textured, subtly colored surface. The desired effect is a translucent, light appearance that enhances the wood’s natural characteristics while lending it a brighter and more modern tone. The key challenge with whitewashing engineered wood is the thin veneer. Excessive sanding to prepare the surface can easily sand through the veneer, exposing the core material and irreparably damaging the flooring.

Before undertaking a whitewashing project on engineered wood, carefully inspect the floor and determine the thickness of the wear layer. Check with the flooring manufacturer, if possible, to ascertain the sanding limit. If the veneer is very thin (less than 2mm), whitewashing via sanding and staining may not be a viable option. Alternative methods, such as applying a tinted polyurethane finish, might be more appropriate in such cases.

Key Point 1: Assessing the Suitability of Engineered Wood for Whitewashing

The primary factor determining the success of whitewashing engineered wood flooring is the thickness of the wood veneer. Generally, a veneer of at least 3mm is desirable for any type of sanding and refinishing, including whitewashing. Floorings with thinner veneers may not withstand the sanding required to prepare the surface for the whitewash stain. Attempting to sand too thin a veneer can result in exposing the underlying core, requiring replacement of the entire board or section of flooring. It's crucial to accurately measure or determine the wear layer thickness before proceeding. Contacting the flooring manufacturer and gathering any technical specifications about the flooring is vital.

Surface finish is another factor. Some engineered wood floors come with a very durable factory finish, often containing aluminum oxide. This type of finish is extremely resistant to abrasion and can be difficult to sand through completely. Thoroughly removing such a finish is essential for the whitewash stain to properly penetrate the wood. Failure to do so will result in a blotchy or uneven finish. Testing a small, inconspicuous area is highly recommended to assess how easily the existing finish can be removed.

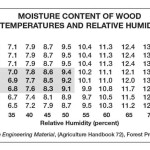

The type of wood used for the veneer also impacts the final result. Different wood species react differently to stain. Some hardwoods, such as oak, have open pores that readily absorb stain, resulting in a more pronounced grain pattern. Other woods, like maple, have tighter grains and may require more coats of whitewash to achieve the desired effect. Understanding the characteristics of the wood species is crucial for selecting the appropriate whitewashing product and technique.

Key Point 2: The Whitewashing Process: Step-by-Step Guide

Assuming the engineered wood flooring is deemed suitable for whitewashing, the process involves preparation, application, and sealing.

Preparation: The first step is thorough cleaning. The floor must be completely free of dirt, dust, grease, and any other contaminants. Use a wood floor cleaner specifically designed for engineered wood. Avoid using excessive water, as it can seep into the seams and damage the core. Next, carefully sand the floor to remove the existing finish. Use a fine-grit sandpaper (120-150 grit) and sand in the direction of the wood grain. Avoid applying excessive pressure, and be mindful of the veneer thickness. Vacuum thoroughly to remove all sanding dust, and then wipe down the floor with a tack cloth.

Application: The choice of whitewashing product depends on the desired level of opacity and the wood species. Options include diluted latex paint, specifically formulated whitewash stains, or lime wash products. When using latex paint, dilute it with water to the desired consistency, typically a ratio of 1:1 or 1:2 (paint to water). For whitewash stains, follow the manufacturer's instructions. Apply the whitewash using a brush, roller, or rag. Work in small sections, and immediately wipe off the excess with a clean cloth. This allows the wood grain to show through and prevents the finish from becoming too opaque. Apply multiple thin coats, allowing each coat to dry completely before applying the next, to achieve the desired level of whitewash. Lightly sand with a very fine-grit sandpaper (220 grit) between coats to ensure a smooth finish.

Sealing: Once the whitewash is completely dry, apply a protective sealant. A water-based polyurethane is recommended for engineered wood, as it provides good durability and will not yellow over time. Apply several thin coats, allowing each coat to dry completely before applying the next. Lightly sand with a very fine-grit sandpaper (220 grit) between coats for a smooth, even finish. The sealant will protect the whitewashed finish from wear and tear and make it easier to clean.

It's imperative to test the entire process on an inconspicuous area of the floor – such as a closet or under furniture – before tackling the entire room. This allows for adjustments to the dilution ratio, application technique, and sealant choice to achieve the perfect look.

Key Point 3: Potential Challenges and Precautions

Whitewashing engineered wood flooring can present several challenges, particularly with thinner veneers and existing finishes. Proper planning and precautions are crucial to avoid costly mistakes. One of the most common problems is sanding through the veneer. This can happen quickly and unexpectedly, especially with aggressive sanding techniques or uneven pressure. Therefore, it's crucial to use the finest possible sandpaper and monitor the sanding progress closely. If any signs of the core material appear, stop sanding immediately.

Uneven stain absorption is another potential issue. This can occur if the floor is not properly cleaned or if the existing finish is not completely removed. The result is a blotchy or inconsistent whitewashed finish. To avoid this, ensure the floor is scrupulously cleaned and sanded before applying the whitewash. Performing a test area will assist in determining the suitability of the technique and the evenness of the result.

Another challenge is the potential for the whitewash to yellow over time. Oil-based sealants can cause yellowing, particularly in light-colored finishes. Therefore, it is crucial to use a water-based polyurethane sealant specifically designed for light-colored wood finishes. These sealants are formulated to resist yellowing and maintain the integrity of the whitewashed look. Properly applying and maintaining seal coats is also critical to protecting the integrity of the whitewashed visual.

Moisture is also a concern when working with engineered wood. Excessive water during cleaning or application can seep into the seams and damage the core. Therefore, use a damp mop instead of a wet mop, and avoid puddling water on the floor. Ensure that the whitewash and sealant are completely dry before exposing the floor to moisture. Furthermore, it is always advisable to install a moisture barrier underneath the engineered floor prior to instillation to protect it from excessive moisture.

Finally, consider the grain pattern of the wood. Some wood species have more prominent grain patterns than others, which can affect the final look of the whitewashed floor. If a more subtle whitewash is desired, choose a wood species with a finer grain pattern or use a more opaque whitewash product. Experimentation with different products and techniques is key to achieving the desired aesthetic.

Engineered Oak White Wash Lacquered Wood Flooring 15mm X 3mm 190mm

Whitewash Hardwood Floors Wood Flooring La

Whitewash Flooring The Many Shades Of White Elmwood Reclaimed Timber

Trendy Whitewashed Hardwood Floors

Engineered Oak Winter Dawn Whitewash Lacquered Wood Flooring 20mm X 6mm 190mm

Whitewashed European Oak Engineered Wood Flooring 14mm X 190mm Lacquered Brilliant

Rustic Matt Lacquered Parquet Herringbone Engineered Wood Flooring Trendy

Engineered Oak White Washed Rustic Brushed Matt Lacquered 14mm X 3mm 190mm

Carpenters Choice 110mm Whitewashed Oak Brushed Lacquered Engineered Wood Flooring Direct

How To Whitewash Hardwood Floors The Right Way Engineered Wood Whitewashed Flooring Oak

Related Posts