Best Power Tool for Cutting Laminate Flooring Edges at Home in Singapore

Laminate flooring is a popular choice for homeowners in Singapore due to its affordability, durability, and ease of installation. However, achieving a professional-looking finish often requires precise cuts, especially along edges and around obstacles. Selecting the appropriate power tool is crucial for efficient and accurate cutting, ensuring a seamless and aesthetically pleasing result. The optimal tool choice depends on various factors, including the complexity of the cuts, the thickness of the laminate, and the user's skill level.

This article provides a comprehensive overview of the best power tools for cutting laminate flooring edges at home in Singapore, considering their advantages, disadvantages, and specific applications. It offers guidance on choosing the right tool for different scenarios and emphasizes the importance of safety precautions during operation. Understanding the capabilities and limitations of each tool will enable homeowners to make informed decisions and achieve professional-quality results in their laminate flooring projects.

Circular Saw: Power and Precision for Straight Cuts

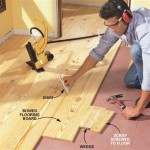

The circular saw is a staple in many workshops and is well-suited for making long, straight cuts in laminate flooring. Its powerful motor and sharp blade can quickly and efficiently cut through laminate planks, saving time and effort on large projects. When selecting a circular saw for laminate flooring, consider the blade type. A fine-tooth blade specifically designed for cutting manufactured materials, such as laminate, is essential to minimize chipping and splintering along the cut edges. These blades typically have a higher tooth count and a specialized tooth geometry that produces cleaner and smoother cuts.

One significant advantage of the circular saw is its versatility. It can be used for a wide range of cutting tasks beyond laminate flooring, making it a valuable tool for general home improvement projects. However, using a circular saw for laminate flooring requires careful attention to detail and proper technique. It is crucial to secure the laminate plank firmly to prevent it from moving during the cut. Using clamps or a workbench with built-in clamping mechanisms can greatly enhance stability and accuracy. Additionally, it is recommended to use a guide rail or straight edge to ensure that the cut is perfectly straight and consistent.

Despite its power and efficiency, the circular saw is not the best option for intricate cuts or tight corners. Its large size and limited maneuverability can make it challenging to navigate complex shapes and achieve precise corner cuts. Furthermore, the circular saw can generate a significant amount of dust and noise, which can be disruptive and require adequate ventilation and hearing protection. Safety is paramount when using a circular saw. Always wear safety glasses to protect the eyes from flying debris, and consider wearing a dust mask to minimize inhalation of dust particles. Familiarize yourself with the saw's operating instructions and safety features before use. Practicing on scrap material can help develop the necessary skills and confidence to make accurate and safe cuts on laminate flooring.

Jigsaw: Versatility for Curves and Intricate Shapes

The jigsaw is a versatile power tool that excels at cutting curves, circles, and other intricate shapes in laminate flooring. Its narrow blade allows for precise maneuvering, making it ideal for cutting around obstacles such as pipes, door frames, and irregularly shaped walls. When selecting a jigsaw for laminate flooring, it is important to choose a model with variable speed control. This feature allows the user to adjust the cutting speed to match the material and the complexity of the cut, minimizing the risk of chipping and splintering. A slower speed is generally recommended for delicate cuts and curves, while a higher speed may be suitable for straight cuts on thicker laminate planks.

Like the circular saw, the jigsaw requires a specialized blade for cutting laminate flooring. A fine-tooth blade with a reverse tooth pattern is recommended to prevent the laminate surface from chipping as the blade cuts upwards. The reverse tooth pattern ensures that the teeth pull the material downwards, creating a cleaner cut on the visible surface. Furthermore, it is crucial to choose a blade that is long enough to cut through the thickness of the laminate plank. Using a blade that is too short can result in uneven cuts and increased risk of blade breakage.

While the jigsaw is excellent for intricate cuts, it can be more challenging to achieve perfectly straight cuts compared to the circular saw. Using a guide rail or straight edge can help improve accuracy, but it still requires a steady hand and careful attention to detail. The jigsaw can also generate a significant amount of vibration, which can make it difficult to maintain a consistent cutting line. To minimize vibration, it is important to hold the jigsaw firmly and use a stable work surface. Clamping the laminate plank to the work surface can also help reduce vibration and improve accuracy. The jigsaw typically produces less dust than a circular saw, but it is still recommended to wear safety glasses and a dust mask to protect the eyes and respiratory system. Practicing on scrap material is particularly important when using a jigsaw for the first time, as it allows the user to develop the necessary skills and techniques to achieve accurate and clean cuts.

Multi-Tool (Oscillating Tool): Precision for Tight Spaces and Detail Work

The multi-tool, also known as an oscillating tool, is a highly versatile power tool that is particularly useful for cutting laminate flooring edges in tight spaces and for performing detail work. Its oscillating blade allows for precise and controlled cuts, making it ideal for trimming edges, cutting around door jambs, and making small notches. The multi-tool is especially valuable when working in confined areas where a circular saw or jigsaw would be difficult or impossible to maneuver.

When selecting a multi-tool for laminate flooring, it is important to choose a model with variable speed control and a wide range of compatible accessories. The variable speed control allows the user to adjust the cutting speed to match the material and the task at hand, minimizing the risk of chipping and splintering. A variety of cutting blades are available for multi-tools, including blades specifically designed for cutting wood, plastic, and metal. For laminate flooring, a fine-tooth blade with a narrow profile is recommended to achieve clean and precise cuts. A plunge-cut blade is particularly useful for making cuts in the middle of a laminate plank, such as when cutting around pipes or electrical outlets.

The multi-tool is relatively easy to use, but it requires a steady hand and careful attention to detail. It is important to hold the tool firmly and apply gentle pressure to avoid damaging the laminate surface. The oscillating motion of the blade can generate heat, so it is important to allow the tool to cool down periodically to prevent overheating. The multi-tool produces a minimal amount of dust compared to a circular saw or jigsaw, but it is still recommended to wear safety glasses to protect the eyes from flying debris. One of the key advantages of the multi-tool is its ability to make flush cuts, which are essential for trimming laminate flooring edges along walls or under door frames. To make a flush cut, simply position the blade flat against the surface and allow the oscillating motion to cut through the material. The multi-tool is a valuable addition to any homeowner's toolkit, particularly for those who frequently undertake home improvement projects that require precise and controlled cutting.

Laminate Flooring Cutter: Specialized Tool for Straight Cuts

A laminate flooring cutter is a specialized tool designed specifically for cutting laminate planks. It operates much like a large paper cutter or guillotine, using a long, sharp blade to shear through the laminate material. One of the primary advantages of a laminate flooring cutter is its clean, chip-free cuts. Because the cutting action is a shear rather than a saw, it minimizes the risk of splintering or chipping the laminate surface, resulting in a professional-looking finish. Unlike power tools, a laminate flooring cutter does not produce dust or noise, making it a quieter and cleaner option for indoor use. This is particularly beneficial in residential settings where noise and dust can be disruptive.

Laminate flooring cutters are relatively easy to use. Simply place the laminate plank on the cutter, align the cut line with the blade, and press down on the handle to shear through the material. Most laminate flooring cutters have adjustable guides to ensure accurate and consistent cuts. The tool requires minimal setup and cleanup, making it a convenient option for quick and efficient cutting. While laminate flooring cutters are excellent for straight cuts, they are not suitable for curved or intricate cuts. Their primary function is to make clean, straight cuts across the width of the laminate plank. This limitation means that they are not a sole solution for projects that require cutting around obstacles or creating custom shapes.

When choosing a laminate flooring cutter, it is important to consider the maximum cutting width and thickness capacity. Ensure that the cutter can accommodate the width and thickness of the laminate planks being used. High-quality laminate flooring cutters typically have a durable construction and a sharp, long-lasting blade. It's also important to note the portability of the cutter. While some are designed to be lightweight and easy to transport, others are larger and more suitable for stationary use. Safety is also a consideration when using a laminate flooring cutter. Keep fingers clear of the blade and always use the tool on a stable, level surface. While laminate flooring cutters are a valuable tool for many laminate flooring projects, they are best utilized in conjunction with other power tools, such as a jigsaw or multi-tool, to handle intricate cuts and detail work.

Safety Considerations for All Tools

Regardless of the chosen power tool, prioritizing safety is paramount when cutting laminate flooring. Before commencing any cutting operation, always wear appropriate personal protective equipment (PPE), including safety glasses to protect the eyes from flying debris, and a dust mask or respirator to minimize inhalation of dust particles. Hearing protection, such as earplugs or earmuffs, is recommended when using noisy tools like circular saws.

Familiarize yourself thoroughly with the operating instructions and safety features of each power tool before use. Ensure that the tool is in good working order, with sharp blades and properly functioning safety guards. Never operate a power tool if it is damaged or malfunctioning. Securely clamp or hold the laminate plank in place to prevent it from moving during the cut. This will improve accuracy and reduce the risk of accidents. Maintain a clear and uncluttered work area to prevent tripping hazards and ensure that you have ample space to maneuver the tool safely.

Always disconnect the power tool from the electrical outlet before changing blades or performing any maintenance. Never leave a power tool unattended while it is running. After completing the cutting operation, thoroughly clean the work area and store the power tool in a safe and secure location. By adhering to these safety guidelines, homeowners can minimize the risk of accidents and injuries while cutting laminate flooring.

Laminate Floor Cutter Flooring Cutting Tool Wood Saw Vinyl Tile Plank Made In China Com

Portable Laminate Vinyl Flooring Cutting Tools Cutter Plank Made In China Com

Vinyl Laminate Flooring Cutting Tool Pvc Spc Wpc Siding Cutter Floor Plank Made In China Com

Wood Router Basics Rockler

Rockler Flush Cut Router Jig

Edge T With A Router

How To Repair Laminate Flooring Handyman Tips Singapore

Ultimate Guide To Diy Vinyl Floor Installation In Singapore Flooring Wood Parquet Decking

Aiko 18v 4 0ah 65mm Hydraulic Cable Cutter Tool Model Ed 65c

Aiko 18v 5 0ah 105mm Hydraulic Cable Cutter Tool Model Ed 105c

Related Posts