Best Flooring Options for Enclosed Motorcycle Trailers

Selecting the right flooring for an enclosed motorcycle trailer is a crucial decision that impacts the safety, longevity, and overall functionality of the trailer. The flooring must withstand the weight and potential movement of motorcycles, resist wear and tear from loading and unloading equipment, and provide a safe and secure surface for transport. This article explores various flooring options for enclosed motorcycle trailers, outlining their advantages and disadvantages to assist in making an informed decision.

Durability and Load Capacity Considerations

The primary function of motorcycle trailer flooring is to bear the weight of the motorcycles and any associated equipment. Therefore, durability and load capacity are paramount considerations. The selected flooring must be robust enough to handle the concentrated weight of motorcycles, which can range from several hundred to over a thousand pounds each. The flooring's ability to resist deformation, cracking, and other forms of degradation under heavy loads is essential for long-term performance.

Options like plywood, while relatively inexpensive, might require reinforcement, especially for heavier motorcycles. Thicker plywood grades can provide better load-bearing capacity but may increase the trailer's overall weight. Diamond plate aluminum offers excellent durability and a high load capacity but is generally more expensive. Rubber flooring and coin flooring are durable options that can withstand heavy loads and provide a degree of cushioning, but their long-term performance under constant stress should be carefully considered.

When evaluating load capacity, it's crucial to consider not only the static weight of the motorcycle but also the dynamic loads associated with movement during transit. Braking, acceleration, and cornering can exert significant forces on the flooring, potentially exceeding the static weight. A flooring material with a higher load rating provides a margin of safety and ensures that the floor can withstand these dynamic forces without failing.

Safety and Traction

Safety is a critical concern when choosing flooring for a motorcycle trailer. The flooring should provide adequate traction to prevent motorcycles from shifting or sliding during transport. A slippery surface can lead to accidents and potential damage to the motorcycles and the trailer itself. The level of traction needed depends on several factors, including the weight of the motorcycles, the type of tires, and the driving conditions.

Smooth surfaces like polished concrete or bare metal can be particularly slippery, especially when wet. Textured surfaces, such as those found in diamond plate aluminum, rubber flooring, and coin flooring, offer improved traction. These textures create friction between the tires and the flooring, minimizing the risk of slippage. Some flooring options also incorporate slip-resistant coatings or additives to further enhance traction.

The ease of cleaning is another aspect of safety to consider. Motorcycle trailers often accumulate dirt, oil, and other debris, which can reduce traction and create a hazardous environment. Flooring that is easy to clean and maintain helps to ensure a safe and secure surface for transporting motorcycles. Non-porous materials are generally easier to clean than porous materials, as they prevent liquids and contaminants from seeping into the flooring.

Installation and Maintenance Considerations

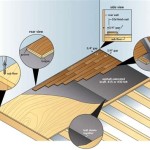

The ease of installation and the level of required maintenance are also crucial factors in selecting the best flooring for an enclosed motorcycle trailer. Some flooring options are relatively easy to install, while others require specialized tools and skills. The installation process can impact the overall cost and time required to prepare the trailer for use.

Plywood, for example, is relatively easy to cut and install, but it may require sealing or painting to protect it from moisture and wear. Diamond plate aluminum can be more challenging to install, as it requires precise cutting and welding or riveting. Rubber flooring and coin flooring can be installed using adhesives or interlocking systems, depending on the specific product.

Maintenance requirements also vary depending on the flooring material. Plywood requires regular inspection and potential resealing to prevent rot and decay. Diamond plate aluminum is relatively low-maintenance but may require occasional cleaning to remove dirt and grime. Rubber flooring and coin flooring may require periodic cleaning and may be susceptible to staining or discoloration over time.

Furthermore, consider the long-term cost of ownership. While some flooring options may have a lower initial cost, they may require more frequent repairs or replacements, leading to higher overall costs in the long run. Investing in a more durable and long-lasting flooring material can potentially save money over the lifespan of the trailer.

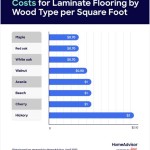

Specific Flooring Material Options and Their Properties

Several flooring materials are commonly used in enclosed motorcycle trailers. Each material offers a unique set of advantages and disadvantages, making it essential to carefully evaluate the specific needs and requirements of the trailer before making a decision. Some popular options include:

Plywood: Plywood is a common and relatively inexpensive flooring option. It provides a solid base for supporting motorcycles and equipment. However, plywood is susceptible to moisture damage and may require sealing or painting to prolong its lifespan. Plywood's load capacity depends on its thickness and grade. Thicker plywood grades offer better load-bearing capabilities but add to the trailer's weight. Regular inspection and maintenance are necessary to prevent rot and decay.

Diamond Plate Aluminum: Diamond plate aluminum offers excellent durability, a high load capacity, and a slip-resistant surface. It is resistant to corrosion and can withstand heavy use and exposure to the elements. Diamond plate aluminum is generally more expensive than plywood but provides a longer-lasting and more durable flooring solution. Installation may require specialized tools and skills. The reflective surface of diamond plate can also provide good visibility inside the trailer.

Rubber Flooring: Rubber flooring provides a durable, slip-resistant, and cushioned surface. It can help to protect motorcycles and equipment from damage during transport. Rubber flooring is available in various thicknesses and textures to suit different needs. It is relatively easy to clean and maintain. However, rubber flooring may be susceptible to staining or discoloration over time. The cost of rubber flooring can vary depending on the quality and thickness.

Coin Flooring: Coin flooring is a type of rubber flooring with a raised coin pattern that provides excellent traction. It is durable, slip-resistant, and easy to clean. Coin flooring is a popular choice for motorcycle trailers due to its aesthetic appeal and functional benefits. It is available in various colors and thicknesses. The cost of coin flooring is generally comparable to other types of rubber flooring.

Epoxy Coatings: Epoxy coatings can be applied over existing flooring, such as plywood or concrete, to provide a durable, seamless, and chemical-resistant surface. Epoxy coatings can be customized with different colors, textures, and slip-resistant additives. They are relatively easy to clean and maintain. However, epoxy coatings may require professional installation. The cost of epoxy coatings can vary depending on the type of epoxy and the size of the area being coated.

Polyurea Coatings: Polyurea coatings are another type of protective coating that can be applied to trailer floors. They offer exceptional durability, flexibility, and resistance to abrasion, chemicals, and UV damage. Polyurea coatings are known for their fast curing times and ability to bond to various substrates, creating a seamless and waterproof membrane. While typically more expensive than epoxy, polyurea coatings provide superior long-term protection and are often used in demanding applications.

Interlocking Tiles: Interlocking tiles, often made of PVC or rubber, offer a modular and easy-to-install flooring solution. These tiles interlock together to create a continuous surface, providing cushioning and slip resistance. They are available in various colors and patterns and can be easily removed or replaced if damaged. Interlocking tiles are a good option for those who prefer a DIY installation and want the flexibility to customize their trailer flooring.

Carpet: While less common, carpet can be used in motorcycle trailers, primarily for aesthetic purposes or to provide extra cushioning. However, carpet is not as durable or easy to clean as other flooring options. It is also more susceptible to moisture damage and staining. If carpet is used, it is essential to choose a durable, low-pile carpet and to protect it from moisture and spills.

Ultimately, the best flooring for an enclosed motorcycle trailer depends on individual needs and preferences. By carefully considering the factors outlined above, it is possible to select a flooring material that provides the optimal balance of durability, safety, ease of installation, and cost-effectiveness.

Trailer Flooring Guide

Flooring For Enclosed Trailer The Garage Journal

G Floor D Ceramic Texture Vinyl Trailer And Modular Unit Flooring

Trailer Flooring Sports Utility Trailers Enclosed Open

Trailer Flooring Guide

Trailer Flooring Liners Cargo Anti Slip Garage Llc

Trailer Flooring Sports Utility Trailers Enclosed Open

Diy Ultimate Trailer Flooring Install Featuring G Floor Small Coin Laminate Build

Enclosed Trailer Upgrades Flooring Painting Walls

22 Best Enclosed Trailer Ideas Decoratoo Motorcycle Trailers Camper

Related Posts