Bamboo Flooring Cost Per Square Metre: A Comprehensive Guide

Bamboo flooring has emerged as a popular and sustainable alternative to traditional hardwood flooring. Its aesthetic appeal, durability, and environmentally friendly characteristics make it an attractive option for homeowners and businesses alike. Understanding the costs associated with bamboo flooring, specifically the cost per square metre, is crucial for budgeting and making informed decisions. This article provides a detailed analysis of the various factors influencing the price of bamboo flooring, helping readers navigate the market and estimate the overall expense of installing this flooring type.

The cost of bamboo flooring per square metre is not a fixed value. It varies based on several elements, including the type of bamboo, manufacturing processes, quality grades, and geographical location. Installation costs also play a significant role in the total expenditure. A thorough understanding of these influencing factors is necessary to accurately assess the financial implications of choosing bamboo flooring.

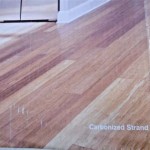

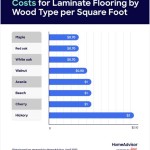

Primarily, bamboo flooring is categorized into three main types: horizontal, vertical, and strand woven. Each type exhibits distinct aesthetic qualities and varying levels of durability, which directly impact the price. Horizontal bamboo flooring is created by pressing horizontal bamboo strips together, showcasing the characteristic bamboo "knuckles." Vertical bamboo flooring, on the other hand, aligns the bamboo strips vertically, resulting in a more linear and uniform appearance. Strand woven bamboo flooring, renowned for its exceptional durability, is manufactured by shredding bamboo stalks into strands, compressing them under extreme pressure, and bonding them with adhesives. This process yields a flooring product that is significantly harder and denser than horizontal or vertical bamboo, therefore commanding a higher price.

Manufacturing processes also influence the cost. The method used to process and treat the bamboo affects its durability, stability, and overall lifespan. Higher quality manufacturing involves meticulous selection of bamboo stalks, precise cutting and shaping, and advanced treatment processes to enhance resistance to moisture, pests, and wear. These enhanced processes translate into a more robust and long-lasting product, justifying a higher price point. Conversely, lower-cost bamboo flooring may utilize less stringent manufacturing standards, potentially compromising its performance and longevity.

Quality grades in bamboo flooring also contribute to the price variation. Bamboo flooring is typically graded based on factors such as the uniformity of color, the presence of imperfections, and the overall consistency of the material. Higher quality grades, characterized by a consistent color palette and minimal imperfections, are usually more expensive. Flooring with visible variations in color or minor defects will typically be priced lower.

Geographical location is another determinant of bamboo flooring costs. Market conditions, supply and demand dynamics, and local economic factors can influence the price per square metre. Regions with higher labor costs or longer transportation distances for bamboo flooring products may experience inflated prices. Furthermore, the availability of local suppliers and installers can affect the overall cost. Metropolitan areas typically have more competitive pricing due to a greater number of suppliers, while rural areas may experience higher costs due to limited availability. The global supply chain's complexities and international trade policies further influence pricing, making it essential for consumers to conduct thorough research and price comparisons within their specific geographic region.

Raw Material Costs and Processing

The raw material cost of bamboo plays a fundamental role in determining the final price of the flooring. Bamboo cultivation and harvesting practices, the maturity of the bamboo stalks used, and the selection of specific bamboo species all affect the initial material expenses. Sustainable harvesting practices that prioritize environmental conservation may contribute slightly to higher raw material costs. The age of the bamboo at harvest is also crucial, as older, more mature stalks generally yield stronger and more durable flooring. The species of bamboo selected also plays a role; some species are naturally denser and more resistant to wear than others, influencing their economic value.

The processing of raw bamboo into flooring planks requires specialized machinery and skilled labor. Once harvested, bamboo stalks undergo a series of processes including slicing, drying, treating, and milling. Drying is a critical step, as proper moisture content is essential for preventing warping and cracking. Treatment processes may involve carbonization, which darkens the bamboo and increases its hardness, or the application of protective coatings to enhance resistance to scratches and stains. Milling precisely shapes the bamboo into interlocking planks or strips, ensuring a seamless and visually appealing finished product. Each of these processing stages incurs costs related to equipment, energy, and labor, which are then factored into the overall pricing of the bamboo flooring.

The type of adhesive used to bond the bamboo strips or strands is another significant factor in the overall cost and quality. Formaldehyde-based adhesives were formerly commonplace, but concerns about indoor air quality have led to the increased use of low-VOC (volatile organic compounds) or formaldehyde-free adhesives. These more environmentally friendly adhesives tend to be more expensive but offer better protection for indoor air quality and align with sustainability goals. Consumers are increasingly concerned about the chemical composition of their building materials, and the demand for low-VOC bamboo flooring is driving a shift towards using safer, albeit pricier, adhesives.

Installation Costs and Subfloor Preparation

Installation costs are a substantial component of the total bamboo flooring expenditure and can vary considerably depending on the complexity of the project and the region’s prevailing labor rates. Professional installation generally ensures a high-quality result, minimizing the risk of improper installation that could lead to warping, buckling, or other problems. However, it also adds to the overall financial outlay. The cost of professional installation depends on factors such as the size of the area to be covered, the intricacy of the floor plan, and the installer's experience and reputation. Complex layouts with numerous corners and obstacles usually demand more time and labor, increasing the installation expenses.

Subfloor preparation is a critical, yet often overlooked, aspect of bamboo flooring installation that can significantly impact the final cost. A level, clean, and dry subfloor is essential for ensuring the stability and longevity of the bamboo flooring. Subfloor preparation may involve leveling uneven surfaces with self-leveling compounds, repairing cracks or imperfections, and cleaning the subfloor to remove debris and contaminants. In some cases, the existing subfloor may need to be replaced entirely if it is severely damaged or unsuitable for supporting the bamboo flooring. These additional preparation steps can add to the overall project cost but are vital for ensuring optimal performance and preventing future problems.

The choice between a floating floor installation and a glue-down installation also influences the installation cost. Floating floors, which are typically installed over a foam or cork underlayment, are generally less expensive to install than glue-down floors. Floating floors can be installed more quickly and easily, reducing labor costs. Glue-down installations, on the other hand, require the use of specialized adhesives and more meticulous application techniques. While glue-down floors may offer greater stability and a more solid feel underfoot, they necessitate more extensive preparation and labor, increasing the installation prices. The optimal installation method depends on the specific type of bamboo flooring, the subfloor conditions, and the homeowner's preferences.

Long-Term Value and Maintenance Considerations

While the initial cost per square metre is a significant consideration, it is important to also evaluate the long-term value and maintenance requirements of bamboo flooring. Properly maintained bamboo flooring can last for decades, providing a cost-effective flooring solution over the long run. Its durability and resistance to wear and tear can reduce the need for frequent replacements, minimizing long-term expenses. Considering the lifespan of different flooring options helps determine which is the most financially sound over extended periods.

Maintenance requirements for bamboo flooring are relatively straightforward and typically involve regular sweeping, vacuuming, and occasional damp mopping. However, proactive measures such as using floor protectors under furniture legs and avoiding excessive moisture can help prolong the lifespan and maintain its aesthetic appeal. More durable finishes, such as those incorporating UV protection, can help prevent fading and wear, reducing the need for refinishing. The cost of cleaning and maintenance products should also be factored into the long-term financial assessment.

Refinishing bamboo flooring can also extend its lifespan and restore its original beauty. While strand woven bamboo is exceptionally durable and may not require refinishing for many years, horizontal and vertical bamboo flooring may benefit from refinishing after a decade or more of use, depending on the level of wear and tear. The cost of refinishing bamboo flooring varies depending on the size of the area, the complexity of the job, and the type of finish applied. Although refinishing involves an additional expense, it is generally significantly less expensive than replacing the entire floor, making it a worthwhile investment for preserving the beauty and longevity of the bamboo flooring.

How Much Does It Cost To Install Bamboo Flooring

How Much Does Bamboo Flooring Cost In 2024 Checkatrade

Cost To Install Bamboo Flooring In 2024 Forbes Home

Cost Of Bamboo Flooring In Nsw 2024 Floor S Floorvenue

Bamboo Flooring S Cost Per Square Metre Foot

Bamboo Flooring S Cost Per Square Metre Foot

Bamboo Flooring Cost

Bamboo Flooring S Cost Per Square Metre Foot

How Much Does Bamboo Flooring Cost In 2024 Checkatrade

List S 2024 Bamboo Flooring Procompare Co Za

Related Posts