Unveiling the Essential Aspects of Lumber Liquidators Formaldehyde Flooring Types

When it comes to flooring options, Lumber Liquidators has established itself as a reputable provider offering a wide range of materials, including formaldehyde flooring. Formaldehyde is an organic compound commonly used in the production of various household products, including building materials and composite wood flooring. To help you make informed decisions, let's delve into the essential aspects of Lumber Liquidators formaldehyde flooring types.

Types and Benefits of Formaldehyde Flooring

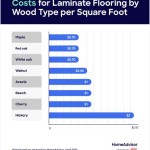

Lumber Liquidators offers two primary types of formaldehyde flooring: laminate and engineered hardwood. Laminate flooring consists of a high-density fiberboard core topped with a photographic image and a wear layer, providing durability and resistance to moisture and scratches. On the other hand, engineered hardwood combines a real wood veneer with a multi-ply core, offering the beauty and warmth of natural wood while maintaining stability.

Formaldehyde acts as a binder in the manufacturing process, contributing to the strength and water resistance of these flooring types. However, it's important to note that advancements in technology have allowed manufacturers to significantly reduce formaldehyde emissions in flooring materials.

Emission Standards and Certifications

To ensure the safety of consumers, Lumber Liquidators adheres to strict emission standards. Their formaldehyde flooring products meet or exceed the California Air Resources Board (CARB) Phase 2 regulations, which set limits on the allowable levels of formaldehyde emissions. Additionally, many of their products carry third-party certifications, such as the GREENGUARD Gold Certification, indicating compliance with rigorous air quality standards.

Environmental Considerations

While formaldehyde is necessary for the durability of these flooring types, concerns have been raised regarding its potential health effects. Lumber Liquidators acknowledges these concerns and takes proactive steps to minimize formaldehyde emissions. They source their raw materials from sustainably managed forests and employ advanced manufacturing techniques to reduce emissions during the production process.

Installation and Maintenance

Formaldehyde flooring from Lumber Liquidators is designed for ease of installation and maintenance. Both laminate and engineered hardwood flooring can be installed using a floating method, which does not require nails or glue. Proper acclimation before installation is crucial to ensure stability. Regular cleaning and occasional deep cleaning will help preserve the appearance and longevity of your flooring.

Conclusion

Lumber Liquidators formaldehyde flooring types offer a durable and versatile option for your flooring needs. With strict adherence to emission standards, third-party certifications, and environmental considerations, you can be confident in the safety and quality of these products. Whether you opt for the practicality of laminate or the natural beauty of engineered hardwood, Lumber Liquidators provides flooring solutions that meet your aesthetic and functional requirements.

Lumber Liquidators Dangerous Wood Flooring The Facts

The Lumber Liquidators Lawsuit Explained And Dangers Of Formaldehyde Flooring Artisan Wood Floors Llc

Lumber Liquidators To Discontinue Formaldehyde Laced Chinese Laminate Flooring Cpsc Aboutlawsuits Com

Lumber Liquidators Stock Plunges After Cdc Hikes Cancer Risk From Some Laminate Flooring Cbc News

Lumber Liquidators Dangerous Wood Flooring The Facts

Lumber Liquidators Customers Still Testing Laminate Floors For Formaldehyde Cbs News

Cdc Revises Lumber Liquidators Flooring Cancer Risk

Condo Blues Can Your Laminate Flooring Kill You

Transform Your Space With Ll Hardwood Unleash The Beauty Of Natural Wood Flooring And Design

Over 100 Toxic Lumber Liquidators Flooring Claims Filed

Related Posts