Essential Aspects of 2 1/4 Inch Engineered Hardwood Flooring

2 1/4 inch engineered hardwood flooring is a popular choice for homeowners due to its durability, versatility, and affordable price point. Unlike solid hardwood flooring, which is made from a single piece of wood, engineered hardwood is constructed from multiple layers of wood that are bonded together with adhesives. This makes it more stable and resistant to warping, shrinking, and expanding.

Here are some of the essential aspects to consider when choosing 2 1/4 inch engineered hardwood flooring:

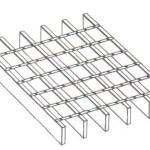

1. Construction

Engineered hardwood flooring is typically constructed from three layers of wood: the backing, the core, and the veneer. The backing is usually made from a thin layer of plywood or HDF (high-density fiberboard). The core is made from a thicker layer of hardwood, such as oak, maple, or cherry. The veneer is the top layer of the flooring, which is made from a thin slice of hardwood that matches the species of the core.

2. Wear Layer

The wear layer is the top layer of the engineered hardwood flooring, which is responsible for protecting the floor from wear and tear. The thickness of the wear layer will determine how durable the floor is. Thicker wear layers will be more resistant to scratches and dents, but they will also be more expensive.

3. Finish

The finish of the engineered hardwood flooring will protect the floor from stains and scratches, and it will also determine the floor's appearance. There are three main types of finishes: urethane, aluminum oxide, and ceramic. Urethane is the most common type of finish, and it is a good choice for homes with pets and children. Aluminum oxide is a more durable finish, and it is a good choice for commercial applications. Ceramic is the most durable finish, and it is a good choice for areas with heavy traffic.

4. Installation

Engineered hardwood flooring can be installed using a variety of methods, including glue-down, nail-down, and float. Glue-down installation is the most permanent method, and it is a good choice for areas with high traffic. Nail-down installation is a more traditional method, and it is a good choice for areas with low traffic. Float installation is a newer method, and it is a good choice for areas with uneven subfloors.

5. Maintenance

Engineered hardwood flooring is relatively easy to maintain. Regular cleaning with a broom or vacuum cleaner is sufficient to keep the floor clean. You should also avoid using harsh chemicals on the floor, as these can damage the finish.

Bruce America S Best Choice Erscotch Oak 2 1 4 In W X 3 T 84 Smooth Traditional Solid Hardwood Flooring 20 Sq Ft Carton The Department At Com

2 1 4 X 1c Better Red Oak Unfinished Engineered Nature Wood Floors

Red Oak 2 1 4 Unfinished Contractor S Choice Collection Engineered Hardwood Flooring By The Garrison Factory

Bruce America S Best Choice Natural Red Oak 2 1 4 In W X 3 T Varying Length Smooth Traditional Solid Hardwood Flooring 20 Sq Ft Carton The Department At Com

2 1 4 X 5 8 Select Hickory Unfinished Engineered Nature Wood Floors

2 1 4 X 3 White Oak Character Unfinished Engineered Hurst Hardwoods

Bruce American Originals Natural Red Oak 3 4in T X 2 1 4 In W Varying L Solid Hardwood Flooring 20 Sq Ft Case Shd2210 The Home Depot

3 4 X 2 1 Gracious Home 50 Yr Prefin Solid Natural White Oak Hardw Cabinets To Go

Malibu Wide Plank Crescent Hickory 1 2 In T X 5 7 W Water Resistant Distressed Engineered Hardwood Flooring 1122 Sq Ft Pallet Hdmstg346efp The Home Depot

Somerset Classic Collection Engineered Red Oak Gunstock 3 1 4