Can I Lay Wood Floor on Concrete? A Comprehensive Guide

The question of whether solid hardwood flooring can be installed directly over a concrete subfloor is a frequently encountered one in the construction and renovation industries. The answer, however, is not a simple yes or no; it depends on several crucial factors relating to the concrete slab's condition, potential moisture issues, and the chosen installation method. Understanding these nuances is essential for ensuring a successful and long-lasting wood floor installation.

Concrete, while a strong and stable foundation for many flooring options, presents specific challenges for wood flooring. Wood is a hygroscopic material, meaning it absorbs and releases moisture from its surroundings. Concrete, being porous, can transmit moisture from the ground, potentially damaging the wood floor over time. Therefore, careful consideration and preparation are paramount before proceeding with any wood flooring installation over concrete.

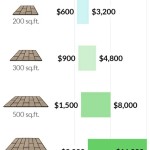

The type of wood flooring is also a significant factor. Solid hardwood flooring, generally thicker and more susceptible to moisture damage, typically requires a more robust subfloor system when installed over concrete. Engineered wood flooring, constructed with multiple layers and a hardwood veneer, tends to be more dimensionally stable and less prone to warping or buckling due to moisture fluctuations. This makes it a more suitable option for direct installation over concrete, provided proper moisture mitigation measures are implemented.

Key Point 1: Assessing the Concrete Slab's Moisture Content

The single most important consideration when installing wood flooring over concrete is the moisture content of the slab. Excessive moisture can lead to a myriad of problems, including warping, cupping, buckling, and the growth of mold and mildew beneath the flooring. Accurately assessing the moisture levels is therefore critical before commencing any installation.

Several methods can be used to test the moisture content of the concrete slab. The most common include the calcium chloride test (also known as the anhydrous calcium chloride test), the relative humidity (RH) test using in-situ probes, and the use of electronic moisture meters designed for concrete. The calcium chloride test involves placing a measured amount of anhydrous calcium chloride under a sealed dome on the concrete surface for a specific period. The weight gain of the calcium chloride, due to moisture absorption, is then used to calculate the moisture vapor emission rate (MVER) in pounds per 1,000 square feet per 24 hours. Acceptable MVER levels typically range from 3 to 5 pounds, depending on the flooring manufacturer's recommendations.

The relative humidity test involves drilling a small hole into the concrete and inserting a probe that measures the RH within the slab. Acceptable RH levels typically range from 70 to 75 percent, again depending on the flooring manufacturer's specifications. Electronic moisture meters provide a quick, non-destructive method of assessing moisture levels but should be used as a preliminary indicator only, as they can be influenced by surface conditions and may not provide a truly accurate representation of the overall moisture content.

If the moisture test results exceed the acceptable limits specified by the flooring manufacturer, moisture mitigation measures must be implemented before installing the wood flooring. Failing to address excessive moisture will almost certainly lead to flooring failure and costly repairs in the future.

Key Point 2: Implementing Effective Moisture Mitigation Strategies

When moisture testing reveals unacceptable levels, various moisture mitigation strategies can be employed to create a suitable environment for wood flooring. These strategies aim to either block or control the transmission of moisture from the concrete slab to the wood flooring.

One common approach involves applying a moisture barrier to the concrete surface. These barriers come in various forms, including liquid-applied epoxy coatings, membrane systems, and self-leveling underlayments with integrated moisture protection. Liquid-applied epoxy coatings create a continuous, impermeable layer that prevents moisture vapor from passing through the concrete. Membrane systems, typically consisting of a polyethylene or similar material, are rolled out over the concrete and sealed at the seams to create a waterproof barrier. Self-leveling underlayments can also incorporate moisture protection properties, providing a smooth, level surface while simultaneously addressing moisture concerns.

Another approach is to create a ventilated subfloor system. This involves installing a network of sleepers or battens over the concrete, creating an air gap between the concrete and the wood flooring. This air gap allows for air circulation, which helps to dissipate moisture and prevent it from accumulating beneath the flooring. Proper ventilation is crucial to ensure the effectiveness of this system; adequate airflow must be maintained to prevent moisture buildup. This method is more commonly used with solid hardwood floors.

Capillary break systems are also used. These systems involve installing a layer of material that interrupts the capillary action of the concrete, preventing moisture from wicking up into the flooring. This can be achieved using specialized underlayments or by creating a layer of crushed stone or gravel beneath the subfloor system.

The choice of moisture mitigation strategy will depend on the severity of the moisture problem, the type of wood flooring being installed, and the specific site conditions. Consulting with a qualified flooring professional is essential to determine the most appropriate and effective solution.

Key Point 3: Selecting the Appropriate Installation Method

After addressing any moisture concerns, the next step is to choose the correct installation method. The appropriate method will depend on the type of wood flooring (solid or engineered) and the existing subfloor conditions.

For solid hardwood flooring, direct gluing to concrete is generally not recommended unless the concrete slab is exceptionally dry and a high-quality moisture barrier has been applied. The movement of solid hardwood due to humidity changes can put significant stress on the adhesive, potentially leading to bond failure and flooring problems. A floating installation over a foam underlayment is a more common approach. This allows the wood flooring to expand and contract freely without being rigidly attached to the concrete.

Another option for solid hardwood is to install a wood subfloor system over the concrete. This typically involves installing sleepers or battens over the concrete, creating a level surface for the wood flooring to be nailed or screwed to. This method provides a more solid and stable base for the flooring and allows for better airflow and moisture management, but it requires raising the floor height, which may not be feasible in all situations.

Engineered wood flooring offers more flexibility in terms of installation methods. It can be glued down directly to the concrete using a suitable adhesive, provided that the concrete is properly prepared and a moisture barrier is in place. The multi-layered construction of engineered wood flooring makes it less susceptible to moisture damage and dimensional changes compared to solid hardwood. Floating installations, similar to those used for solid hardwood, are also common for engineered wood flooring. Many engineered wood flooring products are designed with click-lock systems, which allow for easy and quick installation without the need for glue or nails.

Regardless of the installation method chosen, proper acclimation of the wood flooring is crucial. Acclimation involves allowing the wood flooring to adjust to the ambient temperature and humidity conditions of the installation environment for a period of several days or weeks before installation. This helps to minimize expansion and contraction after installation, reducing the risk of warping, cupping, and gapping.

In summary, laying wood flooring on concrete is a feasible project, but careful planning and preparation are essential. Thoroughly assess the concrete slab's moisture content, implement appropriate moisture mitigation strategies, and select the correct installation method. Consulting with a qualified flooring professional is highly recommended to ensure a successful and long-lasting wood floor installation.

Can You Install A Wood Floor Over Concrete

How To Install A Wood Subfloor Over Concrete Rona

4 Options For Installing Solid Wood Flooring Over Concrete

How To Install Engineered Flooring On Concrete Adm

How To Install Laminate Over Concrete Day 1

A Complete Guide On How To Install Laminate Flooring Concrete

Diy A Complete Guide To Installing Wooden Flooring On Concrete

Ask Fred How Do I Install Wood Floor Below Grade Schedule

Installing Laminate Flooring Over Concrete The Ultimate Guide Aa Floors

Wood Floors Over Concrete Dangers To Avoid

Related Posts