Essential Aspects of Resilient Sheet Flooring Specification

Resilient sheet flooring is a popular choice for commercial and residential applications due to its durability, comfort, and ease of maintenance. To ensure a successful installation, it is crucial to pay attention to essential aspects when specifying this type of flooring.

1. Material Type

Resilient sheet flooring is typically made from materials such as vinyl, rubber, or linoleum. Each material offers unique properties and benefits. Vinyl is known for its durability, water resistance, and versatility, while rubber is preferred for its soundproofing and cushioning qualities. Linoleum, a natural material, is both environmentally friendly and antistatic.

2. Thickness

The thickness of resilient sheet flooring ranges from 2mm to 4mm. Thicker flooring is more durable and can withstand heavier traffic, making it suitable for commercial applications. Thinner flooring is more flexible and easier to install, ideal for residential use.

3. Wear Layer

The wear layer is a protective layer on top of the flooring that resists scratches, stains, and abrasion. Wear layers are typically rated with a mil rating (1 mil equals 0.001 inch). A higher mil rating indicates a more durable wear layer.

4. Backing

The backing of resilient sheet flooring provides support and stability. Backings can be made of felt, foam, or cork. Felt backings are economical and provide cushioning, while foam backings offer superior sound absorption and insulation. Cork backings are environmentally friendly and contribute to the flooring's warmth and comfort.

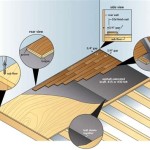

5. Subfloor Preparation

Proper subfloor preparation is essential for a successful resilient sheet flooring installation. The subfloor must be smooth, level, and dry. Any unevenness or moisture issues can cause the flooring to buckle or warp.

6. Adhesive

Adhesive is used to secure resilient sheet flooring to the subfloor. The type of adhesive used depends on the flooring material and the subfloor type. Incorrect adhesive selection can lead to bond failure and flooring damage.

7. Installation

Resilient sheet flooring installation should be performed by experienced professionals to ensure proper adhesion and seam sealing. The flooring is typically rolled out and cut to fit the room, then adhered to the subfloor using adhesive and a roller.

8. Maintenance

Resilient sheet flooring is relatively low-maintenance. Regular cleaning with a damp mop and a mild cleaning solution is sufficient to keep the flooring looking its best. Avoid using abrasive cleaners or harsh chemicals that can damage the surface.

By considering these essential aspects when specifying resilient sheet flooring, you can ensure a durable, comfortable, and attractive flooring solution that will meet the specific needs of your project.

Section 09652 Resilient Sheet Flooring Department Of

Resilient Flooring The Sustainable Specification Construction Specifier

Resilient Flooring The Sustainable Specification Construction Specifier

Luxury Vinyl Tile And Plank Specifications Parterre

Allure Locking Resilient Flooring Vinyl Floating Floor

Resilient Flooring Types Of Used In Buildings

Astm F1700 20 Standard Specification For Solid Vinyl Floor Tile

Pathways Long Specification Cbc Flooring

Astm F1913 19 Standard Specification For Vinyl Sheet Floor Covering Without Backing

System For The Installation Of Vinyl Sheet On Floors In Wet Areas R10 Mapei