Supercoat Liquid Flooring: A Comprehensive Review

Supercoat liquid flooring has emerged as a prominent player in the construction and renovation industries, offering a versatile alternative to traditional flooring options. This review delves into the various aspects of Supercoat liquid flooring, examining its key features, benefits, drawbacks, application process, and ultimately, its suitability for diverse applications. This analysis will provide potential users with a comprehensive understanding of what to expect from Supercoat liquid flooring.

Liquid flooring, in general, represents a category of flooring solutions that are applied in a liquid state and subsequently harden to form a seamless and durable surface. Supercoat, specifically, distinguishes itself through its unique formulation, promising not only aesthetic appeal but also enhanced performance characteristics, such as chemical resistance, impact resistance, and ease of maintenance. Consequently, a thorough assessment of its properties is crucial for making informed decisions regarding its use.

Key Feature 1: Durability and Resistance

A primary consideration for any flooring material is its durability and resistance to wear and tear. Supercoat liquid flooring often boasts superior durability compared to some conventional flooring options. Its formulation typically incorporates epoxy or polyurethane resins, known for their robust mechanical properties. This results in a surface that can withstand heavy foot traffic, impact from dropped objects, and even the movement of vehicles in industrial settings. The specific resistance levels, however, can vary depending on the Supercoat product line and the application thickness.

Chemical resistance is another critical aspect of durability. Supercoat liquid flooring is often designed to withstand exposure to a range of chemicals, including acids, alkalis, solvents, and oils. This makes it particularly well-suited for laboratories, manufacturing plants, and other environments where chemical spills are a potential hazard. The degree of chemical resistance should be carefully reviewed based on the specific chemicals present in the environment where the flooring will be installed. Product data sheets and manufacturer specifications will provide detailed information about the tested resistance levels to various chemicals.

Moisture resistance is also an important consideration. Many Supercoat formulations are designed to be impermeable to water, preventing moisture penetration that can lead to mold growth, structural damage, or the degradation of the flooring itself. This is especially important in areas with high humidity or where frequent cleaning with water is required. However, it's crucial to ensure that the substrate onto which the Supercoat is applied is properly prepared and sealed to prevent moisture from wicking up from below and compromising the bond between the Supercoat and the substrate.

The lifespan of Supercoat liquid flooring is directly related to its durability and resistance. With proper installation and maintenance, a Supercoat floor can last for several years, often exceeding the lifespan of traditional flooring options like tile or carpet. However, factors such as the type of use, the level of foot traffic, the frequency of cleaning, and the presence of harsh chemicals can all affect its longevity. Regular inspection and prompt repair of any damage can help to maximize the lifespan of the floor.

Key Feature 2: Aesthetic Versatility and Customization

Beyond its functional properties, Supercoat liquid flooring offers significant aesthetic versatility. It is available in a wide range of colors, textures, and finishes, allowing for customization to match specific design requirements. This capability makes it suitable for a variety of applications, from residential spaces seeking a modern and seamless look to commercial environments aiming to create a branded and inviting atmosphere. The seamless nature of liquid flooring eliminates grout lines, contributing to a cleaner and more visually appealing surface.

The ability to incorporate decorative elements into Supercoat liquid flooring is another significant advantage. Flakes, aggregates, metallic pigments, and even embedded objects can be added to the liquid mixture before it hardens, creating unique and personalized designs. This allows for the creation of custom logos, patterns, and artwork directly into the floor, adding a distinctive touch to the space. The level of customization is limited only by the imagination and the skills of the installer.

Supercoat can be applied with various finishes, including glossy, matte, and satin. The choice of finish can significantly impact the overall look and feel of the floor. Glossy finishes tend to reflect light, making the space appear brighter and more spacious. Matte finishes offer a more subdued and sophisticated look, while satin finishes provide a balance between the two. The selection of finish should be based on the desired aesthetic and the lighting conditions of the space.

The seamless nature of Supercoat eliminates the visual disruptions caused by grout lines in traditional tile flooring. This creates a smoother and more uniform surface that can enhance the overall aesthetic appeal of the space. The absence of grout lines also reduces the accumulation of dirt and bacteria, making the floor easier to clean and maintain. This is particularly beneficial in environments where hygiene is a top priority, such as hospitals and food processing facilities.

Key Feature 3: Application Process and Maintenance

The application process for Supercoat liquid flooring is crucial to its performance and longevity. Proper surface preparation is essential, including cleaning, grinding, and repairing any cracks or imperfections in the substrate. The substrate must be clean, dry, and free of any contaminants that could interfere with the bond between the Supercoat and the substrate. Failure to properly prepare the surface can lead to adhesion problems, resulting in peeling, cracking, or other forms of failure.

The mixing and application of the Supercoat liquid mixture must be done according to the manufacturer's instructions. This typically involves combining two or more components in a precise ratio and applying the mixture evenly across the surface using specialized tools. The ambient temperature and humidity levels must also be within the recommended range to ensure proper curing of the material. Incorrect mixing or application can result in uneven curing, discoloration, or other defects.

Curing time is another critical factor. The Supercoat needs sufficient time to fully harden and develop its optimal properties. The curing time will vary depending on the specific product formulation, the ambient temperature, and the humidity levels. It is important to restrict foot traffic and other activities on the floor during the curing process to prevent damage. The manufacturer's instructions will provide specific guidance on the recommended curing time.

Maintenance of Supercoat liquid flooring is generally straightforward. Regular cleaning with mild detergents and water is typically sufficient to keep the floor looking its best. Avoid using harsh chemicals or abrasive cleaners that could damage the surface. Promptly clean up any spills to prevent staining or etching. For heavily trafficked areas, it may be necessary to apply a protective sealant or wax coating periodically to maintain the floor's shine and protect it from wear and tear. Regular inspection and prompt repair of any damage can help to extend the lifespan of the floor.

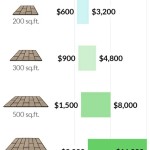

Installation costs can vary significantly based on the size of the area, the complexity of the design, the type of Supercoat product selected, and the location. It is essential to obtain multiple quotes from qualified contractors to compare prices and ensure that the proposed installation process meets the required standards. While the initial investment may be higher than some traditional flooring options, the long-term cost-effectiveness of Supercoat liquid flooring, due to its durability and low maintenance requirements, should be considered.

Supercoat liquid flooring, while offering numerous advantages, is not without potential drawbacks. The initial cost can be higher than some traditional flooring options. The application process requires specialized skills and equipment, making it essential to hire experienced and qualified contractors. Improper installation can lead to problems such as adhesion failures, uneven surfaces, and inconsistent curing. Therefore, careful planning and execution are crucial for a successful Supercoat flooring project.

Overall, Supercoat liquid flooring presents a compelling solution for a wide range of applications, offering a combination of durability, aesthetic versatility, and ease of maintenance. Its resistance to chemicals, moisture, and impact makes it suitable for demanding environments, while its customizable design options allow for the creation of unique and visually appealing spaces. However, careful consideration must be given to the application process, the selection of the appropriate Supercoat product, and the hiring of qualified contractors to ensure a successful and long-lasting installation. By thoroughly evaluating the specific needs of the project and carefully weighing the benefits and drawbacks of Supercoat liquid flooring, informed decisions can be made regarding its suitability as a flooring solution.

Ppg Supercoat Laydown

Has Anyone Used Supercoat Garage Floor Paint Corvetteforum Chevrolet Corvette Forum Discussion

Ppg Supercoat Garage Floor Coating

Renu Refinish

Ppg Supercoat Garage Floor Coating

7 Best Clear Coat For Garage Floors To Buy In 2024

Renu Refinish

Supercoat Industrial Garage Floor Paint 5 Litres Heavy Duty Factory Showroom And Warehouse The

Best Garage Floor Coating In 2024 Top 10 Coatings Review

Renu Refinish

Related Posts