Mohawk Strand Bamboo Flooring: A Comprehensive Guide

Mohawk Industries is a well-recognized name in the flooring industry, offering a broad spectrum of materials and styles. Among its offerings, Mohawk strand bamboo flooring stands out as a durable, sustainable, and aesthetically pleasing option. This article provides a detailed examination of Mohawk strand bamboo flooring, exploring its composition, manufacturing process, advantages, disadvantages, installation, maintenance, and cost considerations.

Bamboo flooring, in general, has gained popularity as an alternative to traditional hardwood flooring. Its rapid renewability makes it an appealing choice for environmentally conscious consumers. Strand woven bamboo, in particular, represents a significant advancement in bamboo flooring technology, offering enhanced strength and durability compared to traditional horizontal or vertical bamboo flooring.

Mohawk strand bamboo flooring is manufactured using a process that compresses bamboo fibers under intense pressure and heat, binding them together with adhesives. This process results in a flooring material that is significantly harder and denser than traditional bamboo or even many hardwood species. The specific type of adhesive used, as well as the pressing parameters, can affect the final product's characteristics, including its hardness, dimensional stability, and emissions of volatile organic compounds (VOCs).

Key Features and Benefits of Mohawk Strand Bamboo

Mohawk strand bamboo flooring offers several key features and benefits that contribute to its appeal: durability, sustainability, aesthetics, and relatively easy maintenance. These characteristics are directly related to the manufacturing process and the inherent properties of bamboo itself.

Durability: One of the most significant advantages of Mohawk strand bamboo is its exceptional durability. The strand woven construction results in a material that is significantly harder than many traditional hardwood species, making it resistant to scratches, dents, and wear. This hardness is typically measured using the Janka hardness scale. Strand woven bamboo often scores higher than oak, maple, and even some exotic hardwoods. This resilience makes it suitable for high-traffic areas in both residential and commercial settings.

The density of strand woven bamboo contributes to its ability to withstand impact and resist indentation. This is particularly important in households with children or pets, or in commercial environments where heavy furniture or equipment may be present. The dense structure also reduces the likelihood of moisture absorption, further enhancing its longevity.

Sustainability: Bamboo is a rapidly renewable resource, making it an environmentally friendly flooring option. Bamboo plants mature much faster than hardwood trees, typically reaching maturity in 3-5 years, compared to decades for hardwoods. This rapid growth rate allows for sustainable harvesting without depleting forest resources. Mohawk, like many reputable manufacturers, often sources bamboo from sustainably managed forests and employs responsible harvesting practices.

The use of bamboo also reduces the pressure on hardwood forests, helping to preserve biodiversity and maintain ecological balance. Choosing bamboo flooring contributes to reducing deforestation and promoting sustainable land management practices. Furthermore, the manufacturing process of strand woven bamboo can be relatively energy-efficient compared to the processing of hardwoods.

Aesthetics: Mohawk strand bamboo flooring is available in a variety of colors, textures, and styles to suit different design preferences. The unique strand woven construction creates a distinctive grain pattern that is often described as a mix of linear and swirling patterns. This gives the flooring a natural and organic look that can complement a wide range of interior styles, from contemporary to traditional.

The available color options range from light, natural tones to darker, richer shades. These colors are typically achieved through staining or carbonization processes. Carbonization involves heating the bamboo to darken its color; however, it can also slightly reduce its hardness. Mohawk offers a variety of finishes, from matte to glossy, allowing for customization to achieve the desired look and feel.

Maintenance: Maintaining Mohawk strand bamboo flooring is relatively straightforward. Regular sweeping or vacuuming is sufficient to remove dirt and debris. Damp mopping with a pH-neutral cleaner is recommended for more thorough cleaning. It is important to avoid using excessive water, as prolonged exposure to moisture can damage the flooring. Mohawk, and other flooring manufacturers, often offer specific cleaning products designed for their bamboo flooring products. These products are usually pH neutral and formulated to not damage the finish of the floor. Using these products helps keep the floors clean and look their best.

Protective mats or rugs should be placed in high-traffic areas and at entrances to prevent scratches and wear. Furniture pads should be used under furniture legs to protect the flooring from indentation. Periodic refinishing may be necessary to restore the flooring's appearance and protect it from further damage. The frequency of refinishing depends on the amount of traffic and wear the flooring experiences.

Installation Considerations for Mohawk Strand Bamboo Flooring

The installation of Mohawk strand bamboo flooring typically involves either a floating or glue-down method. The choice of installation method depends on the subfloor, the room's environment, and personal preference. Proper subfloor preparation is critical for a successful installation, regardless of the method chosen.

Subfloor Preparation: The subfloor must be clean, level, and dry before installing Mohawk strand bamboo flooring. Any imperfections or irregularities in the subfloor can telegraph through to the finished floor. The subfloor should be inspected for moisture content, and any issues addressed before installation. Moisture barriers should be installed to prevent moisture from seeping up from the subfloor and damaging the flooring.

Floating Installation: Floating installation involves interlocking the bamboo planks together without attaching them to the subfloor. This method is generally easier and faster than glue-down installation. An underlayment is typically used between the flooring and the subfloor to provide cushioning and sound insulation. Floating floors are more susceptible to movement with changes in humidity and temperature.

Glue-Down Installation: Glue-down installation involves adhering the bamboo planks directly to the subfloor using a specialized adhesive. This method provides a more stable and solid feel underfoot. It is important to use the correct type of adhesive recommended by Mohawk and to follow the manufacturer's instructions carefully. Glue-down installations are generally more resistant to moisture and movement compared to floating installations.

Acclimation: Proper acclimation is essential for both floating and glue-down installations. Acclimation involves allowing the bamboo flooring to adjust to the room's temperature and humidity levels before installation. This typically involves storing the flooring in the room where it will be installed for several days, allowing it to expand or contract as necessary. Failure to acclimate the flooring properly can lead to gapping, buckling, or other problems after installation.

Potential Drawbacks and Cost Factors

While Mohawk strand bamboo flooring offers numerous advantages, there are also potential drawbacks and cost considerations to keep in mind. These include VOC emissions, susceptibility to moisture, and cost compared to other flooring options.

VOC Emissions: Like many manufactured flooring products, strand bamboo flooring can emit VOCs, particularly formaldehyde. The level of VOC emissions depends on the type of adhesive used in the manufacturing process. It is important to choose Mohawk strand bamboo flooring that is certified by organizations such as FloorScore or CARB (California Air Resources Board) to ensure low VOC emissions. These certifications indicate that the flooring has been tested and meets strict emission standards. Look for labels indicating compliance with these standards to ensure better indoor air quality.

Susceptibility to Moisture: While strand woven bamboo is more resistant to moisture than traditional bamboo flooring, it is still susceptible to damage from excessive moisture. Prolonged exposure to water or high humidity can cause the flooring to swell, warp, or delaminate. It is important to avoid using Mohawk strand bamboo flooring in areas with high moisture levels, such as bathrooms or laundry rooms, unless proper precautions are taken. Proper ventilation and moisture control are essential in these areas.

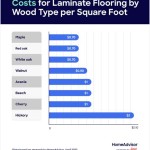

Cost Considerations: The cost of Mohawk strand bamboo flooring can vary depending on the style, finish, and installation method. Generally, strand woven bamboo is more expensive than traditional bamboo flooring, but it is often comparable in price to hardwood flooring. Installation costs can also vary depending on the complexity of the job and the installer's rates. Consider factors such as the cost of the flooring material, underlayment (if needed), adhesive (if needed), and labor when budgeting for a Mohawk strand bamboo flooring project.

The long-term cost-effectiveness of Mohawk strand bamboo flooring should also be considered. Its durability and longevity can result in lower replacement costs over time compared to less durable flooring options. Additionally, its sustainable properties can contribute to environmental benefits and potentially increase property value.

In conclusion, Mohawk strand bamboo flooring represents a compelling option for those seeking a durable, sustainable, and aesthetically pleasing flooring solution. Its strand woven construction provides exceptional strength and resistance to wear, while its rapid renewability makes it an environmentally responsible choice. By carefully considering the installation requirements, potential drawbacks, and cost factors, consumers can make an informed decision about whether Mohawk strand bamboo flooring is the right choice for their needs.

Natural Interiors Strand Sense

Mohawk Hilea Bamboo Flooring Review American Carpet Wholers

Hardwood Natural Strand Bamboo Factory Flooring Liquidators

Mohawk Hardwood Flooring

Hawa Bamboo Strand Woven Solid Carbonized 3 4 X 37 7 8

Bamboo Flooring Performance Floor Central

Antique Strand Woven Solid Bamboo Flooring China Floor Made In Com

Mohawk Hardwood Flooring

Mohawk Heritage Woods 7 5 X 1 2 Engineered Rust Hickory Premium 27 41 Sq Ft Ctn

Mohawk Sendera Birch 6 5 X 3 8 Engineered Snowy Premium 26 15 Sq Ft Ctn

Related Posts